How Many Types of Filter Plates?

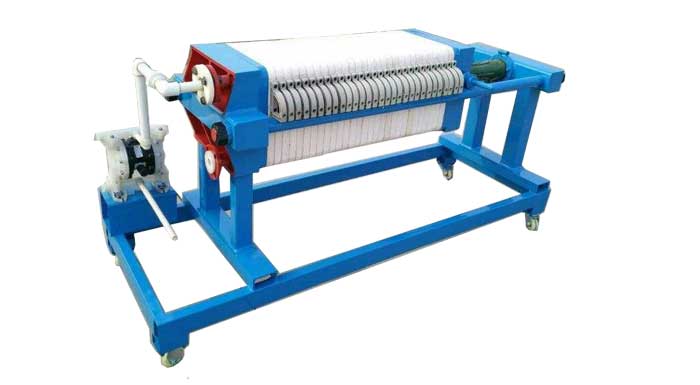

Filter press is a kind of filtration equipment for solid-liquid separation. Filtration takes place in its core part – filter chamber, which is composed of filter plates.

High efficiency sludge filtering requires a properly sized filter press combined with a proper filter cloths and filter plates. So the filter press plates must be corrosion-resistant and strong.

Filter press plates are variously classified on the basis of their materisls, their structure, and their uses as follows:

(1.) Filter Plate Types on the Basis of Materials

Filter plates of filter press includes polypropylene filter plate, polyethylene filter plate, cast iron filter plate and stainless steel filter plate.

(2.) Types on the Basis of Structure

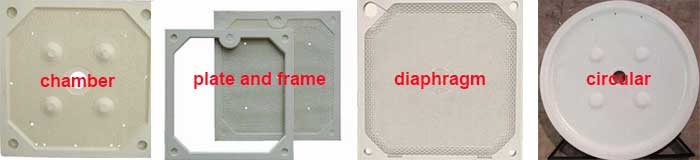

Filter plate of filter press is divided into chamber filter plate, plate and frame filter plate, diaphragm press filter plate and circular filter plate.

(3.) Types on the Basis of Uses

Plate and frame type filter plate is composed of a solid filter plate and a hollow filter plate. It is mainly used in the oil industry. It can also be used as a kind of fine filtration equipment, which is suitable for industries with very few solid materials.

Chamber filter plate is composed of several filter plates with holes in the middle. It can be applied to most industries, with the characteristics of fast filtering speed and high filtering pressure.

Diaphragm press type filter plate is composed of a filter plate with a hole in the middle and a membrane plate which can be inflated to the inside. After filter pressing, air is pumped into the inner part of the membrane plate to further squeeze the filter cake and press it twice to further reduce the liquid content in the filter cake.

Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology) Filter Press [Definition, Components, Types & Comparison]

Filter Press [Definition, Components, Types & Comparison] 10 Common Types Filter Press Prices

10 Common Types Filter Press Prices What Is Bag Filter | Bag Filter Types | How To Choose A Right Bag Filter

What Is Bag Filter | Bag Filter Types | How To Choose A Right Bag Filter