Learn More About Filter Press (45 Filter Press Terminology)

1. Pressure Filtration

Under the action of driving force or other external forces, the liquid in the suspension passes through the filter medium, and the solid particles are intercepted by the filter medium, so as to separate the solid from the liquid.

2. Filtrate

The liquid that flows out through the filter medium when the suspension is filtered.

3. Clarifier

Liquid separated by settling operation.

4. Materials

A general term for all kinds of separation objects (such as suspension, emulsion, etc.) separated by filter press.

5. Filter Cake

The solid concentrate obtained by the pressure filtration of the suspension during the pressure filtration process.

6. Feeding Time

The time required to add material to the machine.

7. Unloading Time

The time required to remove the cake (or residue) from the machine.

8. Filter Cycle

The time taken by the filter press for a complete filtration cycle.

9. Feed Pressure

The pressure of the material at the inlet.

10. Washing Pressure

When the filter cake is washed, the input pressure of the washing medium.

11. Press Pressure of Diaphragm

After the diaphragm, the extrusion pressure formed by pressing in the pressing medium.

12. Blowing Pressure

When the filter cake is dried, the input pressure of high-pressure air.

13. Filter Cake Thickness

The thickness of the cake on the filter surface.

14. Open Flow

The plate and frame filter press or box filter press structure in which filtrate filtered from each filter plate is discharged directly out of the machine

15. Open Flow One-Way Washing

There is only one washing channel in the filter press. The washing channel enters the washing liquid from each filter plate, and the washing liquid after washing is directly discharged from the structure outside the machine by each filter plate.

16. Open Flow Two-Way Washing

There are two washing channels in the filter press, two washing channels enter the washing liquid from the odd number plate, and the washing liquid after washing is directly discharged from the washing structure outside the machine from the even number plate.

17. Open Flow Cross Washing

There are two washing channels in the filter press, one washing channel enters the washing liquid from the odd plate for washing, and the washing liquid after washing is directly discharged from the even plate; the other washing channel enters the washing liquid from the even plate for washing, and the washing liquid after washing is directly discharged from the washing structure outside the machine from the odd plate.

18. Undercurrent

The structure that the filtrate filtered from each filter plate of plate and frame filter press or box filter press is collected in the internal channel of the machine and then discharged.

19. Undercurrent One-Way Washing

There is only one washing channel in the filter press. The washing channel enters the washing liquid from each filter plate, and the washing liquid after washing is collected in the internal channel and discharged out of the washing structure.

20. Undercurrent Two-Way Washing

There are two washing channels in the filter press, two washing channels enter the washing liquid from the odd number plate for washing, and the washing liquid after washing enters the inner channel of the machine from the even number plate for collection and then exits the washing structure outside the machine.

21. Undercurrent Cross Washing

There are two washing channels in the filter press, one is from the odd number plate into the washing liquid for washing, and the washing liquid after washing is from the even number plate into the internal channel for collecting and discharging; the other is from the even number plate into the washing liquid for washing, and the washing liquid after washing is from the odd number plate into the internal channel for collecting and discharging out of the washing structure.

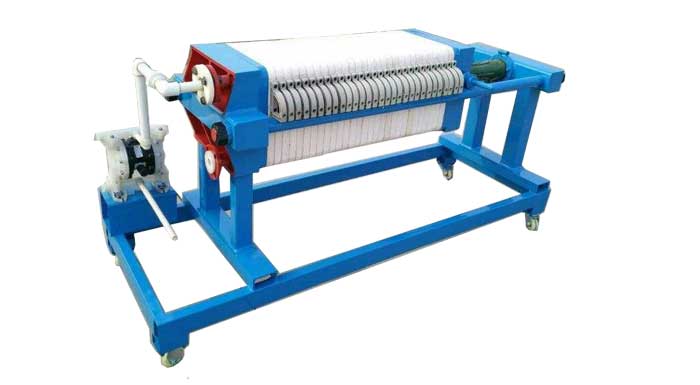

22. Manual Filter Press

The filter plate, filter medium and filter frame of the plate frame (or box type) filter press are pressed by manpower through the lead screw.

23. Mechanical Filter Press

The filter plate, filter medium and filter frame of the plate frame (or box type) filter press are pressed by the mechanical device driven by the motor.

24. Hydraulic Filter Press

The filter plate, filter medium and filter frame of plate frame (or box type) filter press are pressed by hydraulic device.

25. Suspension Filter Press

The filter plate of the filter press is suspended on the upper crossbeam.

26. Side Beam Filter Press

The structure of the filter plate and the filter frame of the plate frame (or box type) filter press supported on the two beams on both sides of the filter press.

27. Collecting Tray

The disc mechanism or trolley used to collect the capillary water leakage of the filter cloth or the flushing water of the filter cloth in the filter press. It is also called “liquid tank”.

28. Turnover Panel

It is installed in the lower part of the filter press, and is used for the water leakage of the guide filter cloth or the washing water of the filter cloth.

29. Filter Plate

In the filter press, a plate-shaped part used to support the filter cloth with a mesh or strip-shaped filtrate guide groove on its surface.

30. Feed Plate

The plate structure in the filter press is used to connect the feed pipe and the filter chamber, so that the slurry can enter the filter chamber smoothly.

31. Filter Frame

In the plate and frame filter press, the frame shaped parts that form the filter chamber with the filter plate.

32. Chamber Filter Pate

The concave filter plates on both sides of the Chamber filter press form the parts of the filter chamber.

33. Press Diaphragm

The elastic diaphragm is installed in the filter chamber of the filter press and used for extruding the filter cake.

34. Girders

The horizontal beam used in plate frame (or box type) filter press to support pressing plate, pulling plate and filter plate, and to connect thrust plate and oil cylinder seat.

35. Compressing Plate

The plate and frame (or box type) filter press can move on the crossbeam and compress the parts of the filter plate and the filter frame under the action of the pressing device.

36. Thrust Plate

The plate and frame (or box type) filter press is fixedly connected with the cross beam, and the filter plate and the parts of the filter frame are pressed together with the pressing plate.

37. Filter Cloth

Filter media such as textiles and non-woven fabrics for filtration

38. Automatic Plate and Frame Filter Press

Plate and frame filter press which can automatically complete some operation procedures.

39. Chamber Filter Ppress

A pressurized filter which consists of a chamber filter plate and a filter medium arranged alternately to form a filter chamber.

40. Automatic Filter Press

Chamber filter press that can automatically complete some operation procedures.

41. Horizontal Automatic Chamber Filter Press

Automatic chamber filter press with filter plates arranged horizontally.

42. Vertical Automatic Chamber Filter Press

Automatic chamber filter press with filter plates arranged in vertical direction.

43. Membrane Filter Press

The chamber filter plate is embedded with a pressing diaphragm, which can squeeze the filter cake after the pressure filtration.

44. Filter Chamber

The space for pressure filtration in the filter press.

45. Filter Chamber Volume

The maximum volume of filter cake in the filter chamber.

How Many Types of Filter Plates?

How Many Types of Filter Plates? Filter Press [Definition, Components, Types & Comparison]

Filter Press [Definition, Components, Types & Comparison] 10 Common Types Filter Press Prices

10 Common Types Filter Press Prices Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair

I need a quote for a small filter press , manual operation , for 0.5 Cu-Ft . Regards!