How Much Does Crush Sand Plant Cost & SetUp Procedure

How Much To Start A Crush Sand Plant?

How Much Does Crush Sand Plant Cost and SetUp Procedure [PDF DOWNLOAD]

Initial Investment

1. License

First of all, a sand and stone factory must obtain a mining license, business license, mining license, safety production license, etc. The processing of these certificates needs to pay a certain administrative fee.

2. Mine Sites

The capital input for purchasing mines and renting production sites shall be consulted with mine owners or departments in accordance with local market conditions.

Medium Investment

1. Equipment Cost

[Blasting Equipment] Rock drills, Blasthole Drills, Air Impact wrench, etc.

[Transportation Equipment] Forklifts, Trucks, Excavators, Loaders, Dumpers, etc.

[Processing Equipment] Production of stone materials can not be separated from feeder, crusher, vibrating screen, belt conveyor and other basic equipments. In sand making plants, additional equipment such as sand making machine and sand washing machine are also needed.

[Electrical System] Motor, Starter Cabinet, Cable, Transformer, Air Compressor, etc.

2. Earthwork Cost

The civil and steel structures of crush sand plant buildings, silos, crushers, vibrating screens and belt conveyors also need corresponding budgets. Usually the price of this part is about 10% of the cost of equipment.

3. Environmental Cost

Environmental protection is the general direction of crush sand plants. Many governments explicitly require that environmental protection standards be met before it can be put into operation. Specific environmental protection measures include installing dust removal equipment at main dust-raising points, sealing production workshops, hardening plant roads, greening the surrounding environment, etc.

Late Investment

1. Logistics Cost

Machines used for crush plants belong to large-scale mining equipment. If we choose a foreign manufacturer, we should consider the long-distance logistics cost of the equipment. Price order: air transport > land transport > water transport.

2. Human Cost

According to the needs of production and management, it is necessary to employ employees with professional skills, such as accountants, equipment operators, drivers, supervisory and control room attendants, all of which belong to the soft inputs from crush sand and gravel plants.

How To Setup A Crush Sand Plant [Procedure]

1. Processing Formalities

First of all, it is necessary to apply for business license, tax registration certificate and application report to the land and resources department.

2. Site Selection

Site of crush sand plant has a very important impact on normal production operations. Therefore, many factors should be taken into account in site selection, and the surrounding environment should be investigated to ensure that the site can meet the needs to the greatest extent.

The following 7 tips should be considered in the site selection of crush sand plants:

- ① Convenient traffic conditions, electricity and water.

- ② Far away from residential areas, it is advisable to choose the downwind outlet of the dominant wind.

- ③ The distance between the factory area and the blasting point should be at least more than 200 meters according to the industry standard.

- ④ The area of the plant area, as well as the yard and capacity of raw materials and finished materials.

- ⑤ Storage and transportation of finished materials.

- ⑥If the site does not meet the requirements, the cost of site leveling should be considered initially.

- ⑦ Geological conditions, natural disasters, etc.

3. Equipment Configuration

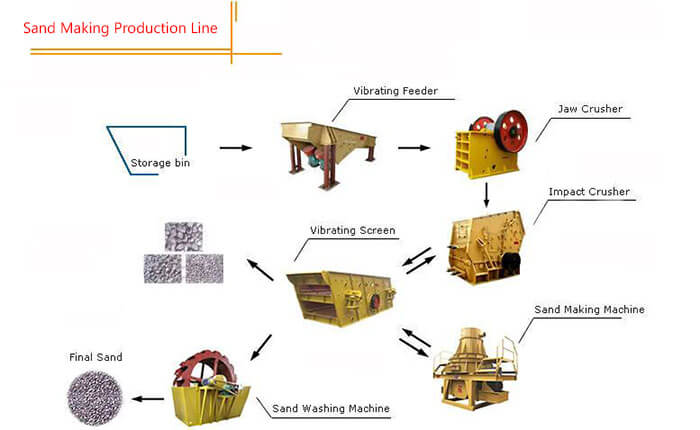

Generally, the production process of crush sand plant is as follows:

Silo → Feeding → Crushing → Sand Making → Screening → Sand Washing → Finished Sand

Each process is connected by a conveyor. Therefore, the crush sand plants mainly include feeder, crusher, sand making machine, vibrating screen, sand washing machine and belt conveyor. Other supporting equipment may also include dust collectors, stone washers,powder separator, packaging, waste water treatment facilities and so on.

However, due to the different processing standards of users, the size and hardness of raw materials are also different, and the specific equipment configuration will be different.

Above is the basic process and the investment budget involved in the setup of a crush sand plant. From the above introduction, it can be found that the medium investment make up a large portion of the crush sand plant.

Therefore, customers should invest more energy in selecting equipments, fully understand the qualification, scale and after-sales services of many manufacturers, and make reasonable decisions.

Portable Sand Plant VS Fixed Sand Plant

Portable Sand Plant VS Fixed Sand Plant A 800 TPH Sand Making Plant Details

A 800 TPH Sand Making Plant Details Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate

I am interested