How Gold Flotation Plant Work

Flotation is one of the most commonly used processes in gold mines, which can effectively enrich gold ore and achieve separation.

The work of the gold flotation plant mainly includes the following steps:

1. Crushing & Grinding

The gold ore is crushed and ground to the appropriate particle size, and then finely ground by grinding equipment to release the metal minerals in the gold ore. The process of crushing and grinding plays a crucial role in subsequent flotation and metal extraction. Therefore, it is necessary to strictly control the process parameters of crushing and grinding to ensure the suitability of ore particle size and grinding fineness.

In this process, equipment such as vibrating feeders, jaw crushers, cone crushers, vibrating screens, ball mills, conveyors, etc. are usually required.

2. Pulp Preparation

Mix the crushed ore with water in a certain proportion to prepare a pulp. The density and concentration of the pulp should be adjusted according to the specific situation to ensure the smooth progress of the flotation process.

During the slurry preparation process, a stirrer is required to ensure the uniformity and stability of the slurry. The agitator can stir the slurry by rotating the stirring blades to prevent it from settling or layering.

3. Reagents Addition

Add a series of reagents to the pulp, including flotation agents, adjusters, and additives. The dosage and type of these reagents need to be selected based on the specific properties of the ore to improve flotation efficiency.

4. Mixing

Mix the pulp thoroughly to ensure sufficient contact and mixing between the reagents and ore particles. The intensity and time of stirring should be adjusted according to the ore properties and process requirements to achieve the best flotation effect.

5. Flotation

After stirring, the pulp enters the flotation machine and separates gold from other ores through the interaction between bubbles and ore particles. The flotation machine usually uses mechanical agitation and bubble adsorption to capture gold particles in the rising foam, so as to achieve gold flotation.

The pulp is obtained by primary roughening, secondary selection, and primary sweeping to obtain the concentrate. During the sorting process, the primary roughening concentrate and tailings are returned to the primary roughening flotation machine for further selection, while the secondary tailings slurry is returned to the primary roughening flotation machine for further selection.

The flotation machine is a key equipment in the gold ore flotation process, with low investment and high efficiency. It is like a large container that can fully react with the slurry and reagents, making it easier to obtain the final gold concentrate. There are many structural forms of flotation machines, and the most commonly used is the mechanical stirring flotation machine.

6. Desliming

The foam after flotation contains gold particles and certain ore impurities, which is called flotation foam concentrate. In order to obtain pure gold products, the flotation foam needs to be deslimed to remove the mud and impurities.

7. Concentration

The tailings slurry is pumped to a concentration cyclone for concentration, and the concentrated overflow is transported to a high-efficiency tailings thickener for further concentration. The overflow water from the thickener is then returned for reuse. The concentrated bottom flow enters the plate filter press for filtration, and the filter cake is transported by a belt conveyor to the concentrate bin for storage.

There are many factors that affect gold flotation, including grinding fineness, pulp concentration, flotation reagent dosage, flotation machine inflation, flotation time and frequency, etc. So, choosing the appropriate flotation process flow and equipments are very important.

Gold Washing Plant | Gold Wash Process & Equipment

Gold Washing Plant | Gold Wash Process & Equipment Flotation Machine | Working | Applications | Types | Select

Flotation Machine | Working | Applications | Types | Select Types of Flotation Reagents and Their Function

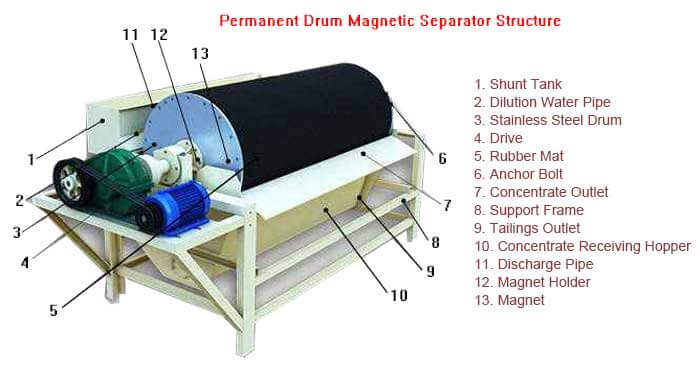

Types of Flotation Reagents and Their Function What is Permanent Magnetic Drum Separator | How Does It Work

What is Permanent Magnetic Drum Separator | How Does It Work