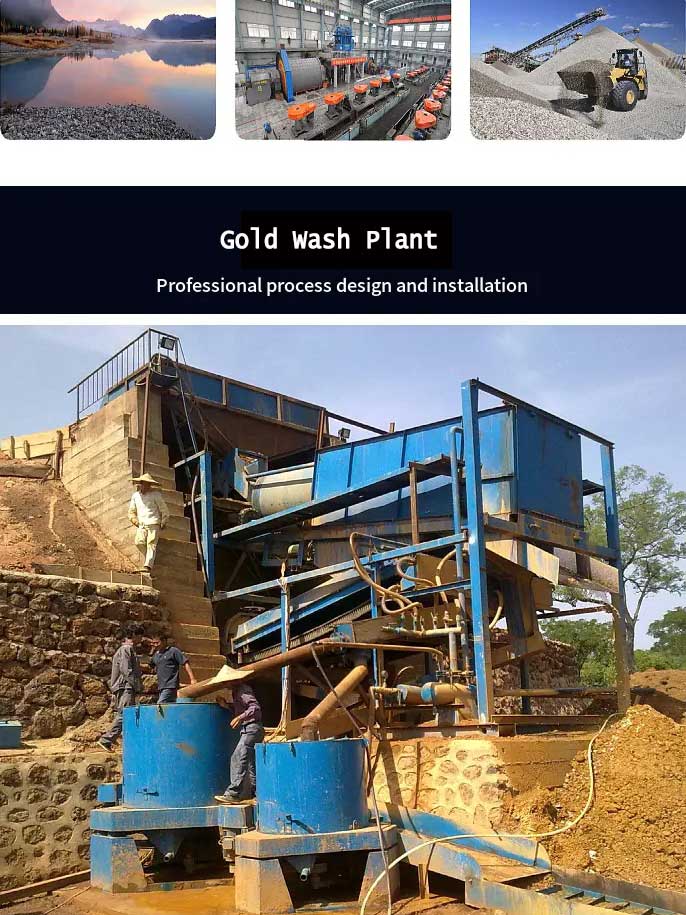

Gold Washing Plant | Gold Wash Process & Equipment

A gold washing plant is a factory specialized in processing gold ore and extracting gold elements through a series of processes and technologies. Its main workflow includes steps such as crushing, screening, flotation, and leaching etc., aiming to separate gold or other valuable minerals from the original ore.

- Crushing: The raw ore first goes through a crushing process, usually including a jaw crusher and a cone crusher. The jaw crusher initially crushes the raw ore into small pieces and then sends them to the cone crusher for further crushing until small particles of 0-10mm are reached.

- Screening & Washing: The crushed ore is screened through a circular vibrating screen or trommel screen. The upper layer products may need to be further crushed and enter the cone crusher together with the middle layer products for further crushing and screening. During the screening process, the soil on the gravel surface needs to be washed with water to realize the separation of soil and gold. Gold washing machines need to be installed in this process.

- Flotation: The material overflowing from the cyclone first undergoes preferential flotation, in which specific chemical reagents (collectors and foaming agents) are mixed with gold powder. Under specific pH conditions, gold particles are attached to bubbles and float to the surface of the slurry, thereby separating from waste rock and other impurities.

- Concentration & Filtration: The flotation gold concentrate is concentrated to remove excess water and impurities. Subsequently, residual impurities are further removed through filtering equipment to obtain a relatively pure gold concentrate.

- Cyanide leaching: Next, the gold concentrate will undergo the cyanide leaching process. In this step, a cyanide solution is used to react with the gold concentrate, allowing the gold to dissolve in the solution and separate from other minerals and impurities.

- Electrolysis & Refining: After cyanide leaching, a solution containing gold will undergo electrolysis. During the electrolysis process, gold will gradually deposit on the cathode, forming metallic gold. Subsequently, these metallic gold will be refined to remove any residual impurities and obtain high-purity gold.

- Wastewater Treatment: A large amount of wastewater will be generated throughout the entire gold washing process. These wastewater must undergo strict treatment before discharge to ensure compliance with environmental standards and avoid pollution to the environment.

- Concentrate Enrichment: Through specific enrichment equipment, such as sluice box or centrifugal gold concentrator, the selected concentrate is further enriched to increase the gold content.

Here are some common gold washing equipments:

Centrifugal Gold Concentrator

The centrifugal gold concentrator can achieve a recovery rate of over 90% for various heavy ores with a particle size less than 4mm. Suitable for sorting minerals with relatively balanced particle size and significant density differences. In block gold mines, when the iron content is high, it is necessary to first carry out iron removal treatment, and then use this equipment for sorting to achieve better results.

The centrifugal gold concentrator is composed of a feeding tube, a frame, a tailings tank, a driving motor, a vertical shaft, and beneficiation components. The mineral processing components are divided into two layers: inner and outer. The inner layer is a conical body with a head, made of stainless steel and equipped with circular grid bars. There are many small holes on the cone wall. The outer layer is made of ordinary steel plate, forming a closed water jacket with the inner layer.

Gold Shaking Table

The gold shaking table utilizes an asymmetric reciprocating inclined bed surface for inclined flow separation. Through the combined action of gravity, lateral water flow impulse, and inertia and friction generated by the asymmetric reciprocating motion of the bed surface, the ore particles are layered according to their specific gravity and particle size, thus achieving effective extraction of gold ore. The recovery rate of the shaking table is relatively high, and the investment cost is relatively low.

Gold Sluice Box

Gold Sluice Box is a professional gold mining tool primarily used for separating and collecting gold particles from ores. Its working principle is to separate gold and other valuable substances by subjecting the ore to the action of water flow and gravity in the chute through specific structures and designs.

The gold box has a large processing capacity, is not prone to hardening, has low investment costs, and an ideal recovery rate. It is mainly used for coarse selection operations after screening of placer gold mines, as an enrichment equipment.

Jig Machine

The jigging machine utilizes a vertically rising variable speed water flow to loosen the ore particles, and then stratifies and separates them according to the differences in density and particle size. Particles with high density settle faster, while particles with low density settle slower, thus achieving the separation of mineral particles with different densities.

Jigs can separate minerals with larger or finer particle sizes but significant differences in specific gravity. It has a large processing capacity and is suitable for rough selection and enrichment.

Flotation Machine

Flotation machine is composed of tank body, ore feeding device, mixing device, inflation device, foam scraper, tailings discharge device and some auxiliary devices, such as reagent adding device, liquid level control device, electric control cabinet, etc. The flotation machine can be suitable for different types and characteristics of ores. According to production needs, the flotation machine can be adjusted and assembled to achieve the best beneficiation effect.

In addition, flotation machines have high sorting accuracy, large processing capacity, low operating costs, and high degree of automation, which makes them widely used in mining, metallurgy, and chemical industries.

Trommel Screen

Trommel screen usually used for ore washing and screening operations, it is particularly suitable for handling placer gold mines with moderate or small clay content. It has a large processing capacity, good screening effect, and a low equipment failure rate.

Portable Gold Washing Machine

A portable gold washing machine is a device specifically designed for cleaning and separating gold ore. Its main feature is portability, which facilitates gold extraction operations in the wild or at different locations.

Portable gold washing machines are usually gold processing equipment that integrates feeding, screening, and chute gold selection. Specifically, a portable gold washing machine may include one or more drums or screens for carrying and transporting ore, and may also be equipped with a high-pressure water gun or spray system for spraying high-pressure water columns onto the ore to further clean the ore surface. Through these cleaning and screening processes, gold and other valuable minerals can be separated from the ore.

In addition, there are also some other gold washing equipments, such as mining agitator washer, spiral chute, gold trommel scrubber, log washer etc., which play an important role in gold extraction and processing.

How Gold Flotation Plant Work

How Gold Flotation Plant Work Coal Preparation Plant | Coal Preparation Process | Coal Washing

Coal Preparation Plant | Coal Preparation Process | Coal Washing Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing Distinguish: Preshrinking | Water Wash | Sand Wash | Frosted

Distinguish: Preshrinking | Water Wash | Sand Wash | Frosted

I am interested to buy a complete train for extraction of gold from gold ore. Please share your different plant capacities and respective prices.

Okay, Mr Bhavesh patel

We will contact you as soon as possible to assist you in choosing the most suitable gold washing production line