How To Identify Circular and Linear Vibrating Screen

Screening is to separate materials with different properties, which is an essential part of the aggregate production line. Screening machines are classified into different types according to their structure and motion characteristics, among which circular vibrating screen and linear vibrating screens are the most commonly used mining equipment. In this article, will introduce top 9 tips differences between linear vibrating screen and circular vibrating screen.

1. Different Movement Trajectories

Circular vibrating screen makes use of centrifugal force produced by the rotation of the eccentric block in the vibrator to make the screen box, vibrator and other parts make a forced continuous circular or approximate circular movement. The materials on circular vibrating screens move with screen boxes in a round movement trajector.

The linear vibrating screen uses the vibration force of the vibrating motor to make the material be thrown up on the screen and moved forward in a straight line.

2. Different Exciters

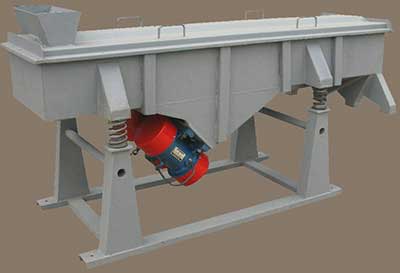

The linear vibrating screen exciter is composed of 2 shafts. It works on the principle of vibrating motor, so it is also called double shaft vibrating screen.

The circular vibrating screen is also called single shaft vibrating screen because the exciter is one shaft and works with an inertia motor.

3. Different for Plugging

The material on the linear vibrating screen moves smoothly on the screen panels. If the material is fed unevenly or the humidity viscosity of the material is large, it is easy blocked.

The material of the circular vibrating screen moves in parabola shape on the screen panels, which makes the material disperse as much as possible, and the material stuck in the screen hole can also jump out, and the plugging is less.

4. Different Installation Inclination

In the production of linear vibrating screen, the inclination angle of screen surface is small, and the height of screen is reduced, which is convenient for the screening plant layout.

Circular vibrating screen usually has a 15-20° installation angle, so as to change the movement speed of materials along the screen panels and improve the screening efficiency.

5. Different Materials

The linear vibrating screen is mainly made of light plate or stainless steel plate.

The material of the circular vibrating screen is thick, and the box body is made of manganese steel, which can resist the impact of the material in the screening process.

6. Different Shape & Structure

The linear vibrating screen can adopt a totally closed structure, without dust overflow, which is more conducive to environmental protection.

While the exciter of circular vibrating screen is arranged above the center of screen box gravity, which is conducive to the rapid spread of materials, and the treatment capacity is higher than that of the linear vibrating screen.

7. Different Applications

Linear screen is mainly used to screen fine particles, materials with light specific gravity and low hardness, mainly inclede dry powder, fine particles or micro powder, which are usually used in food, chemical, building materials and pharmaceutical industries.

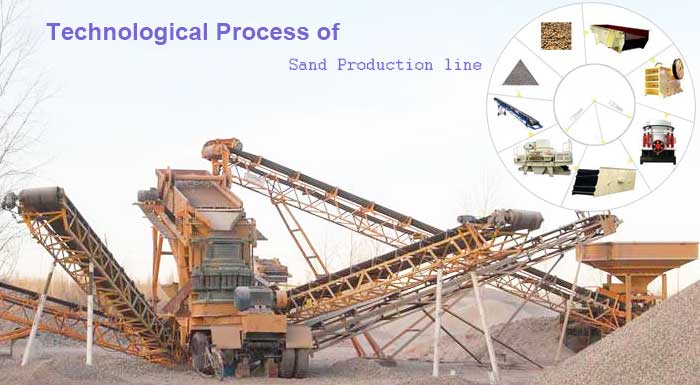

Circular vibrating screen is mainly used for screening materials with large ratio, large particle size and high hardness, which is widely used in mines, coal preparation plant, quarries, etc. In addition, circular vibrating screens can also be used for some materials that are not easy to be screened.

8. Processing Capacity

Circular vibrating screen can turn the spindle, so that the vibration direction is opposite to the material movement direction, and the material movement speed along the screen surface is reduced, thus the screening efficiency is improved.

9. Environmental Protection

The linear vibrating screen can adopt a fully closed structure with no dust overflow, which is more conducive to the protection of the environment.

Circular Vibrating Screen VS Linear Vibrating Screen

In the field of mine crushing, circular vibrating screen is widely used. In the actual production, the choice of circular vibrating screen or linear vibrating screen mainly depends on the types of materials and application fields handled by users. The purpose of screening is different, the selection of equipment is also different.

How To Choose Linear Vibrating Screen

How To Choose Linear Vibrating Screen Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Top 10 Vibrating Screen Types & Working Principle [How To Choose] 5 Tips of Vibrating Screen Problems & Solutions

5 Tips of Vibrating Screen Problems & Solutions Become A Vibrating Screen Expert in 3 Minutes

Become A Vibrating Screen Expert in 3 Minutes