Become a Sand Washer Expert in 3 Minutes

In the production of artificial sand, the sand cleaned by the sand washer is cleaner and of better quality, so the sand washer has gradually become an important equipment of the artificial sand production line.

This article will share the install, test run, operate and maintenance work in the daily operation of the sand washing machine, so that you can become an expert in the sand washer within 3 minutes.

How to Install

1. After the sand washing machine is transported to the site, the user shall immediately check whether all parts are complete and damaged. After confirming that the machine is intact, it can be installed.

2. The user shall design the foundation construction drawing of the sand washing machine according to the specific situation of the site, and install the sand washing machine firmly on the solid concrete foundation.

3. When installing the spiral sand washing machine, the inclination angle must be guaranteed according to the requirements of the installation drawing.

4. The motor of the sand washing machine is installed on the guide rail to adjust the tightness of the belt. The belt pulley and the motor pulley shall be installed in parallel.

5. After adjustment, turn the rotor plate for several revolutions to check whether it is stuck or collided.

How to Test Run

When the sand washer is in operation, it must be put into trial operation.

I. No Load Operation:

- 1. After the motor is started, the sand washer shall operate stably without abnormal vibration.

- 2. Bearing temperature shall not exceed 35 ℃.

- 3. Sand washer shall be idle for 2-4 hours, check whether all connections are loose, and adjust them.

II. Load Operation:

- 1. The sand washing machine can operate under load only when it operates well under no load.

- 2. The sand washing machine operates stably without abnormal vibration.

- 3. The bearing temperature shall not exceed 40 ℃.

- 4. No dust is allowed to enter each sealing place.

- 5. Measure the actual power of the motor without abnormal fluctuation.

- 6. The load operation lasts for 5-6 hours, and it can be put into operation after confirmation.

How to Operate

1. Before starting the sand washing machine, check whether there are sundries in the drain hole, and clean it in time to prevent the drain hole from blocking.

2. Carefully check whether all fasteners are fully tightened and whether nuts are tightened, especially the new sand washing machine.

3. Check whether the lubricating oil reaches the height. If not, add lubricating oil in time.

4. Check whether the belt of the sand washing machine is in good condition. If the belt is damaged, replace it. If there is oil on the belt, wipe it with a rag.

5. Check whether the protective device is in good condition. If any unsafe factors are found, remove them in time.

6. If any abnormality is found after starting the sand washing machine, stop the sand washing machine immediately. It can only be started again after troubleshooting.

7. The sand washing machine is allowed to start without load.

8. During sand washing, the flushing water pipe shall be released first, and then the material shall be fed.

At the same time, the spray direction and the height of overflow baffle shall be adjusted to effectively wash the sand and maintain a proper water depth.The water supply shall be moderate, so as to clean the sand and prevent the sand from overflowing along the notch.

When feeding, pay attention to the uniform addition, not too much and too fast, too much will easily damage the machinery due to overload, and too little will affect the output.

9. When the sand washing machine is stopped, it shall be carried out according to the sequence of procedures. It is forbidden to shut down the machine or continue feeding after it is shut down.

How to Maintenance

1. The bearing is the most easily damaged part, which needs regular maintenance and regular oil filling to increase the bearing life.

2. Check once every two months, and replace immediately in case of serious wear.

If the sand washing machine uses rolling bearings, it is necessary to check the bearing seats at both ends of the spiral shaft frequently, and pay attention to the reliability of the bearing sealing device. In case of wear, water seepage and sand immersion, stop the machine immediately, replace the sealing device and clean and lubricate the bearing. Generally, the rolling bearing can be oiled every 5000 hours.

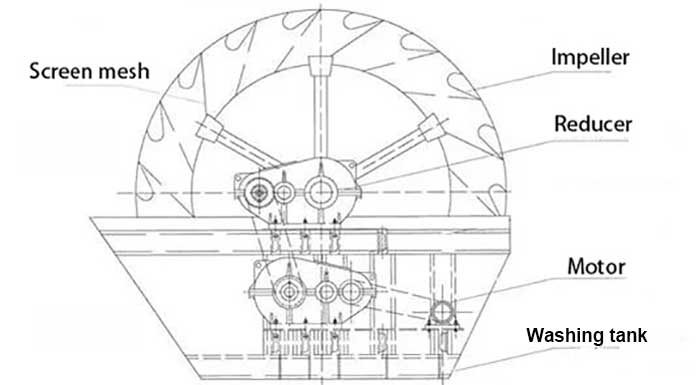

3. Pay attention to the noise of the machine at any time; the operation of the screw shaft, V-belt, sealing device, water pipe and other components; whether the motor and reducer are overheated, and whether the bolts of each part are fastened, etc.

4. Gearbox shall be cleaned and replaced with oil after 3-6 months of operation, and the bearing pedestal shall be replaced with new grease every 6-12 months.

5. Electrical device of large sand washing plant must have reliable grounding device. Check the motor wiring frequently for wear and leakage to avoid accidents.

6. Sand washer seasonal maintenance is mainly to change engine oil, fuel oil, antifreeze and add rantifreeze facilities.

7. It is strictly prohibited to touch the body, adjust, clean, repair and other operations when the sand washing machine is running.

Become A Vibrating Screen Expert in 3 Minutes

Become A Vibrating Screen Expert in 3 Minutes 11 Common Faults of Sand Washer and Solutions

11 Common Faults of Sand Washer and Solutions Is Wheel Sand Washer Better Than Spiral Sand Washer ?

Is Wheel Sand Washer Better Than Spiral Sand Washer ? Types of Sand Washer

Types of Sand Washer

![What is Sand Casting | Sand Casting Process [10 Steps] What is Sand Casting | Sand Casting Process [10 Steps]](https://www.beidoou.com/wp-content/uploads/2024/09/sand-casting-process.jpg)

Screw conveyor silica sand washing