6 Sludge Treatment Processes and Technologies | Cmparative & Analysis Report

At present, sludge treatment and disposal technology mainly refers to sludge thickening, regulation, dehydration, stabilization, drying or incineration, so as to achieve the purpose of sludge reduction, stabilization and harmlessness.

At present, the mainstream sludge treatment technologies include anaerobic digestion, aerobic fermentation, deep dehydration, thermal drying, lime stabilization technology and incineration technology.

1. Anaerobic Digestion

Sludge anaerobic digestion refers to the process in which facultative bacteria and anaerobic bacteria decompose the biodegradable organic matter in sludge into carbon dioxide, methane and water under anaerobic conditions, so as to stabilize the sludge. Anaerobic digestion is one of the common methods for sludge reduction and stabilization.

Anaerobic digestion of sludge has the advantages of reducing sludge volume, stabilizing sludge properties and producing methane gas.

The traditional anaerobic digestion of sludge has the disadvantages of slow reaction, low degradation rate of organic matter and low production of methane, which limits the advantages of anaerobic digestion technology. According to Bryant’s three-stage theory, hydrolysis is a rate-limiting step in the process of sludge anaerobic digestion.

Therefore, since the 1970s, various physicochemical techniques for anaerobic digestion of sludge, including high temperature thermal hydrolysis, ultrasonic pretreatment, alkaline hydrolysis pretreatment and ozone pretreatment, have been studied. By breaking the cell wall of sludge, the intracellular organic matter is transferred from solid phase to liquid phase, which promotes sludge hydrolysis and improves the effect of sludge anaerobic digestion.

At present, sludge pretreatment technology has developed a variety of processes, such as Cambi thermal hydrolysis, Biothelysis thermal hydrolysis and Monsal enzymatic hydrolysis, which have been widely used in Europe in recent years, and there have been successful applications in Norway, the United Kingdom and Australia.

In view of the limitation of low solid content in traditional sludge anaerobic digestion, the research on anaerobic digestion technology of high solid sludge has also become a hot spot.

At present, a variety of anaerobic digestion technologies with high solid content of sludge have been developed and have been applied in practical projects, such as the HLAD process in Finland, which controls the solid content of sludge entering the pre-reaction tank to 10%-15%, and the gas production efficiency is 30% higher than that of traditional sludge anaerobic digestion.

> Advantages ofAnaerobic Digestion

The anaerobic digestion process can kill some pathogenic bacteria and parasite eggs, so that the sludge can be stabilized and not easy to rot.

Biogas produced by anaerobic digestion process can realize the effective recovery of sludge biomass energy.

Anaerobic digestion can degrade 35% ~ 50% of volatile solids in sludge and reduce the amount of dry solids in sludge, which is conducive to reducing the cost of subsequent sludge treatment and disposal. At the same time, anaerobic digestion helps to improve the sludge dewatering performance, and the sludge volume can be further reduced after dewatering.

> Disadvantages of Anaerobic Digestion

Maintaining the temperature required for anaerobic digestion requires a lot of heat energy.

The retention time of sludge anaerobic digestion process is long, usually up to 20 ~ 30 days, resulting in huge volume of anaerobic digestion tank and complex operation and management.

Methanogens have high requirements for environmental conditions. Strain culture must be carried out in the start-up stage, and the initial commissioning time is long.

After anaerobic digestion, the moisture content of sludge is still high, and subsequent treatment must be carried out. The common methods are thermal drying and deep dehydration.

2. Aerobic Fermentation

Aerobic fermentation is that under aerobic conditions, microorganisms oxidize part of the absorbed organic matter into simple inorganic substances through absorption, oxidation, decomposition and other activities, and release the energy needed for microbial growth activities; while another part of the organic matter is synthesized into new cytoplasm, so that microorganisms continue to grow and reproduce, resulting in more organisms.

The high temperature aerobic fermentation of sludge continuously decomposes the organic matter, which increases the temperature of the reactor, and can kill the pathogens and parasite eggs and make them harmless. The product of aerobic fermentation of sludge at high temperature is called compost, which can be used as soil improver and organic fertilizer.

Sludge high temperature aerobic fermentation should pay attention to the problem of heavy metal pollution of sludge, because the role of aerobic bacteria is easy to produce malignant odor in the treatment process, so odor pollution should be prevented, and the moisture content of treated sludge can generally be less than 40%.

At present, the main process forms of sludge composting are static and dynamic.

♥ Advantages of Aerobic Fermentation

Aerobic fermentation process can kill pathogens and weed seeds in sludge and achieve innocuity.

The aerobic fermentation process can degrade most of the organic matter in the sludge and reduce the moisture content of the sludge to 40%.

The fertilizer made from aerobic fermentation can be used in land to achieve resource utilization.

No additional heat source is needed, and the operating cost is relatively low.

♥ Disadvantages of Aerobic Fermentation

The sludge is unstable, in which heavy metals are difficult to stabilize and the application area is narrow, so it can only be used as fertilizer for landscaping.

It covers a large area.

A large amount of stench is produced in the process of composting, which pollutes the surrounding environment.

3. Deep Dehydration

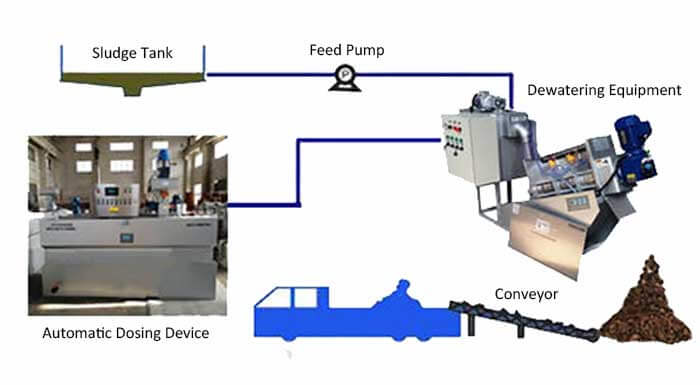

Dewatering reagents, flocculants or coagulants are added to the sludge to change the existing mode and structure of water molecules (mainly interstitial water and capillary water) in the sludge, so that most of the bound water in the sludge is transformed into free water.

After treatment, the moisture content of the sludge can be less than 50%, and finally the free water can be separated by mechanical sludge dewatering machines.

The commonly used additives are ferric chloride (or ferric sulfate, polyferric sulfate) and quicklime.

The sludge deep dewatering equipment is mainly a high-pressure diaphragm frame filter press. By applying pressure from the outside of the sludge, the water in the quenched and tempered sludge is leached and separated, and the mud cake with high solid content is obtained.

⇒ Advantages of Deep Dehydration

The reduction effect is good, and the energy consumption is low.

The area is small and the construction period is short.

The processing time is short.

⇒ Disadvantages of Deep Dehydration

Ferric chloride is highly corrosive and quicklime is easy to scale, which leads to high operation and maintenance cost of high-pressure diaphragm frame filter press.

The stability and sterilization are not enough, it smells a little, and the content of organic matter in the sludge does not decrease.

4. Sludge Thermal Drying

Sludge thermal drying refers to the removal of moisture from sludge by heat transfer between sludge and heat medium. Sludge thermal drying system mainly includes storage and transportation system, drying system, tail gas purification and treatment system, electrical automatic control instrument system and its auxiliary system.

According to the degree of sludge drying, it can be divided into two types: full drying and semi-drying. “full drying” refers to a higher solid content, with a solid content of more than 85% of the dried sludge, while semi-drying mainly refers to a solid content of about 45% and 60% of the dried sludge.

According to the different methods of sludge drying, it can be divided into direct drying and indirect drying. “Direct drying” is the use of hot drying medium (such as flue gas) in direct contact with sludge to transfer heat by convection and take away the evaporated water, also known as thermal convection drying system; “indirect drying” is the use of conduction from the heat medium (such as steam) through the metal wall to transfer heat to the sludge, evaporated water is taken away through carrier gas (such as air) and washed and condensed, also known as heat conduction drying system.

The main sludge dryers are: fluidized bed dryer, drum dryer, belt dryer, turntable dryer, pulp blade dryer, turbine film dryer etc.

¤ Advantages of Thermal Drying

The volume of sludge is significantly reduced, and the volume can be reduced by about 4 times.

After drying treatment, stable products can be formed, and the properties of sludge can be greatly improved.

The dried product is odorless and pathogen-free, which reduces the negative effects related to sludge and makes the treated products more acceptable.

The finished products of drying treatment have a variety of uses, such as fertilizer, soil improver, alternative energy and so on.

¤ Disadvantage of Thermal Drying

Large investment, high energy consumption and high operating cost.

High temperature drying is easy to produce stench.

The dust control in the drying process is strict, and there are hidden dangers in safety.

5. Lime Stabilization Technology

The sludge with 80% moisture content reacts with quicklime according to the mass ratio of 4:1, the temperature in the system rises rapidly to 100 degrees, and the moisture in the sludge is evaporated to complete the process of sludge drying and dewatering. The dried sludge is transported to the outdoor stacking shed through a double screw mixer for stacking and storage.

In order to prevent the secondary pollution in the sludge drying project, the lime dust and malodorous gas can be treated by adding dedusting and deodorizing equipment.

Lime stabilization technology can effectively deodorize, sterilize, inhibit corruption, dehydration and passivate heavy metal ions.

♣ Advantages of Lime Stability

The utility model has the advantages of small investment, low operating cost, small footprint and simple operation and management.

Can effectively eliminate bacteria, and there is no risk of bacterial regeneration.

The drying products are rich in calcium hydroxide, silicon oxide, calcium carbonate and other substances, which can be used as building materials, road foundation accessories, landfill cushion soil, road construction backfill and so on.

Lime stabilized sludge has a high pH value and can be used as a desulphurizer for incineration equipment.

It is especially suitable for emergency or phased disposal.

♣ Disadvantages of Lime Stabilization

Due to the large amount of lime added, the degree of reduction is not high.

The mud cake is strongly alkaline, the land use value is low and the surface is narrow.

The fee for the use of pharmaceuticals is high.

6. Sludge Incineration

Sludge incineration means that the organic matter in the sludge is transformed into CO2, H2O, N2 and so on under the condition of certain temperature and sufficient oxygen, and the heat released in the reaction process is used to maintain the temperature condition of the reaction.

Sludge incineration is the most thorough method of sludge treatment, which can remove all organic matter, kill all pathogens and minimize the volume of sludge.

→ Advantages of Sludge Incineration.

Incineration of sludge can achieve “reduction, stabilization and innocuity” to the greatest extent.

According to the content of heavy metals, the incinerated ash can be directly or treated with heavy metal chelating agents to enter the landfill, and can also be used as building materials or paving roads.

→ Disadvantage of Sludge Incineration

The cost of investment and maintenance is high.

The calorific value of sludge itself is low, and it needs to be mixed with municipal solid waste and coal, so the operation cost is high.

The emission of tail gas is large, which is easy to cause secondary pollution.

The goal of sludge treatment is to achieve reduction, stabilization and harmlessness. Compared with the 6 sludge treatment methods, each has different advantages.

Sludge, Sludge Dewatering, Why & How To Dewater Sludge

Sludge, Sludge Dewatering, Why & How To Dewater Sludge Analysis of 8 Whitening Methods for Kaolin

Analysis of 8 Whitening Methods for Kaolin Lithium Battery Recycling and Treatment Methods

Lithium Battery Recycling and Treatment Methods Dewatering Equipments for Mineral & Sludge

Dewatering Equipments for Mineral & Sludge