Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Vibrating screen is a mechanical equipment that uses vibrating screen panels to classify the mixture which contain different particles according to particle size.

According to different structure and use, vibrating screens usually be devided into many types by the vibrating screen manufacturers. Below wil introduce the top 10 vibrating screens, and how to choose the right vibratory screen?

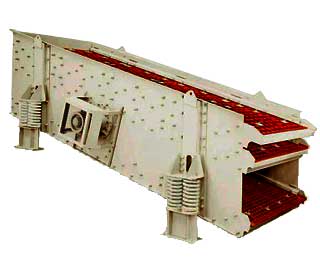

1. linear Vibrating Screen

linear vibrating screen is driven by double vibrating motors. When the two vibrating motors are rotating synchronously and reversely, the excitation force generated by the eccentric block offsets each other in the direction parallel to the axis of the motor, and overlaps into a resultant force in the direction perpendicular to the axis of the motor, so the motion track of the linear vibrating screen machine is a straight line.

Working Principle: The two motor axes of the linear vibrating screen have an angle of inclination in the vertical direction relative to the screen panel. Under the combined force of the exciting force and the self gravity of the material, the material is thrown on the screen surface to jump or move forward in a straight line. Through the multi-layer screen panels, a variety of specifications of materials are generated, and discharged from their respective outlets, so as to achieve screening and classification.

linear vibrating screen is suitable for screening various dry powder or granular materials with particle size of 0.074-5mm, moisture content <7%, and no viscosity. The feed particle size is not more than 10 mm.

2. Circular Vibrating Screen

Circular vibrating screen is a new type of vibrating screen with multi-layer screen and high efficiency. According to the type of materials and the requirements of users, the high manganese steel woven screen, punched screen plate and rubber screen plate can be used. The circular vibrating screen is installed in the seat type. The adjustment of the screen surface angle can be realized by changing the position and height of the spring support.

Working Principle: The motion track of the screen box of the circular vibrating screen is circular. The circular vibrating screen uses the inertia exciter to produce vibration. The main shaft fixed on the screen box is driven by the motor to rotate at high speed, and the eccentric body installed on the main shaft rotates with it, generating centrifugal inertia force, so that the screen box that can freely vibrate will produce vibration similar to the circular track.

Circular vibrating screen is widely used in the materials classification of mining, building materials, transportation, energy, chemical industry and other industries because of its long flowing line and many screening specifications.

3. Elliptical Vibrating Screen

Elliptical vibrating screen is a vibrating screen with elliptical motion track (Elliptical Shale Shaker), which has the advantages of high efficiency, high screening accuracy and wide range of application. Compared with the ordinary sieve machine of the same specification, it has larger processing capacity and higher screening efficiency.

Triaxial elliptical vibrating screen is widely used for the screening operation of sand and stone materials in sand plant. It is the ideal screening equipment for all kinds of mines, quarries and mobile screening stations.

Working Principle: The power is transmitted from the motor to the main shaft of the exciter and the gear vibrator (speed ratio is 1) through the V-belt, so that the three shafts can rotate at the same speed and generate the exciting force. The exciter is connected with the high-strength bolts of the screen box, resulting in elliptical movement.

Materials on the screens do high-speed elliptical movement along with the screen machine, so as to achieve uickly separate, sift and move forward, and ultimately complete the classification of materials.

4. Roller Screen

The working surface of the roller screen is composed of a series of rolling shafts that arranged horizontally, on which there are many screen plates. When working, the fine material passes through the gap between the roller or screen plate, large blocks of materials are driven by rollers, moving to the ends and discharging from the outlets. Roller screens are mostly used in the traditional coal industry.

Working Principle: For the rolling shafts are arranged according to different working angles, the speed of the material is faster when it runs in the position with higher working angle; the speed of the material is slower when it runs in the position with lower working angle.

When two kinds of materials running at different speeds converge at a certain position on the screen surface, they start to move axially, so that the materials are evenly distributed on the screen surface, and the screening efficiency is improved.

5. Rotary Vibrating Screen

Rotary vibrating screen is mainly used for the classification of materials with high screening efficiency and fine screening accuracy. Fully closed structure, no flying powder, no leakage of liquid, no blocking of mesh, automatic discharge, no material storage in the machine, no dead angle of grid structure, increased screen area.

Any particle, powder and mucus can be screened within a certain range. Sieve to 500 mesh or 0.028mm, filter to 5 microns minimum. It can be used for classification, classification and filtration in food, chemical, metal, mining and other industries.

With the help of the heavy hammer installed at the upper and lower ends of the motor shaft, the rotary motion of the motor is transformed into a horizontal, vertical and inclined three-dimensional motion, which is then transmitted to the screen surface to make the material do an outward involute motion on the screen surface.

Working Principle: After the rotary screen is started, the eccentric blocks of different phases at the upper and lower ends of the vibrating motor generate a composite inertia force, which forces the vibrating body of the rotary screen machine to rotate again and again, and the screen frame continuously moves to and fro under the action of the vibration force, and then drives the screen surface to vibrate periodically, so that the materials on the screen surface move in a positive and directional manner together with the screen box. Materials smaller than the screen meshes fall to the lower layer, and the materials larger than the screen meshes discharged from the discharge port.

6. High Frequency Vibrating Screen

High frequency vibrating screen is also called high frequency screen for short. High frequency vibrating screen (high frequency screen) is composed of exciter, pulp distributor, screen frame, supporting, suspension spring and screen, etc. High frequency vibrating screen is the most important screening machine in mineral processing industry, which is suitable for completely wet or dry raw materials.

Working Principle: Different from ordinary screening equipments, high frequency screen adopts high frequency, which destroys the tension on the pulp surface and makes the fine materials vibrate at high speed on the screen, accelerates the separation of useful minerals with large density (specific gravity), and increases the probability of contact between the materials with smaller than the separated particle size and the screen holes.

As a result, high frequency screen results in a better separation conditions, which makes the materials that smaller than the separation size (especially with larger specific gravity), and pulp pass through the screen holes together to complete the screening.

High-frequency vibrating screen is usually operated at an inclined angle 0°-25°, up to 45°, and the operating frequency range is 1500-7200r/m.

7. Grizzly Screen

Grizzly screen is often used for pre-screening before coarse and medium crushing of materials. The mesh size is generally >50mm, but sometimes <25mm.

Grizzly screen has simple and solid structure, no power consumption, no moving parts, low equipment cost and convenient maintenance, but the productivity is low, the screening efficiency is not high, generally 50% – 60%, and the mesh is easy to be blocked.

Working Principle: Generally, the grizzly screen is placed in an inclined position, and the materials are dumped at the high end. Under the action of its own weight, it slides down the screen surface, and the particles smaller than the gap or hole on the screen surface pass through the screen to achieve classification.

The inclination angle of the screen is related to the static friction angle of the material. Generally, the inclination angle is 35°-45°, and the viscosity material can reach about 50°.

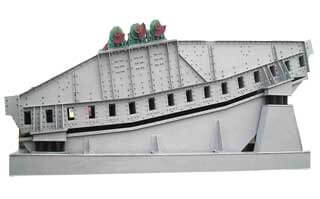

8. Banana Screen

The banana screen adopts a screen plate with multiple sections and different dip angles, the longitudinal section is broken line and the whole screen is like banana shaped.

Banana screen is mainly suitable for the classification of large and medium-sized materials with high content of fine particles, and it can also be used for dehydration, demineralization and desliming.

Working Principle: During operation, the motor is connected with the vibration exciter through the V-belt or soft connection. The motor drives the eccentric shaft to rotate to generate centrifugal inertia force, which forces the screen box to vibrate. After the materials fall into the screen from the feeding inlet, they move forward rapidly under the action of the vibration force, loosely and pass through the screen.

The thickness of the material layer of banana screen from the feeding inlet to the discharging outlet is constant. The ratio of the material quantity to the flow speed on the screen of each section is stable, the material layer is high and uniform. The screening efficiency of banana screen is higher, which is 1-2 times higher than that of other screening machines with the same effective area.

9. Inclined Screen

Heavy inclined screen can be applied to the treatment of debris from quarry, mine and building demolition, the treatment of topsoil, the recycling of construction materials, the screening of gravel, and the screening of gravel and aggregates.

A variety of combination of screen box forms can be woven screen, welded screen, self-cleaning screen, piano wire screen, needle screen, perforated plate screen.

Working Principle: The screen box shaft is driven by the motor installed on the auxiliary frame through three V-belts, the auxiliary frame is rigidly connected with the machine underframe, and the screen box spring is used to support the screen box.

Inclined screen usually adopts 2-4-layer screen panels, and is fixed on the inclined frame at an angle between 15° and 30°. The material can be screened into 3-5 grades at the same time.

10. Horizontal Screen

Horizontal screen has the advantages of both inclined screen and linear vibrating screen. horizontal screen has the features of good screen permeability, large processing capacity and small installation height.

The installation angle of common vibrating screen is 15°-30°, while the installation of horizontal screen is parallel to the ground, or slightly inclined 0-5°. Horizontal screen is an ideal equipment for all kinds of mines, quarries and mobile screening stations.

Working Principle: Horizontal screen is designed with oval stroke. The advantage of this design is that it can change the oval big diameter length and angle of throwing material stroke to meet the best needs of vibrating screen. The oval stroke is easy to adjust by center gear, counterweight wheel and motor speed.

How To Choose Right Vibratory Screen

Different types of vibrating screens can be used for the same material to get different screening effects. The reasonable selection of vibrating screen is an effective way to improve vibration efficiency and maximize economic benefits. Generally, you need to consider the following 5 tips:

1. Characteristics of Materials

When choosing vibratory screen, the material characteristics should be taken into account, including the content of material particles under the screen, the content of difficult screen particles, material moisture, the shape and specific gravity of the material, and the content of clay.

Tips: Heavy vibrating screen is used for materials above 200mm; circular vibrating screen is used for materials above 10mm; linear vibrating screen and high frequency vibrating screen are used for desliming, dewatering and grading.

2. Structure of Vibratory Screen

When selecting the vibratory screen, the screen areas, layer numbers, shape, size and area ratio of the screen holes, as well as the motion mode, vibration frequency and amplitude of the vibrating screen should also be considered.

The screening efficiency of the vibratory screen is related to the motion form of the screens, so the fixed screen is lower than that of the moving screen.

Tips: In order to keep the screens under good working conditions, the ratio of screen length to width should be in the range of 2-3; when there is much viscous mud and high moisture in the material, double deck screens should be avoided as far as possible.

3. Screening Purpose

Vibratory screens need to be selected according to different screening purposes. If it is necessary to pre screen materials, circular vibrating screens are generally used; for the classification and screening of crushed materials, large vibrating screens and probability screens are selected; for the deionization and dehydration of materials, linear vibrating screens are better; if it is necessary to desliminate and clean up materials, probability screens are used.

4. Process Requirements

When selecting the shale shakers, it also needs to be considered according to the processing capacity of the production line, screening method, screening efficiency and the tilt angle of the shale shakers.

5. Professional Vibrating Screen Manufacturer

Professional vibrating screen manufacturers could provide competitive vibrating screen price, diversity customized vibrating screen models, timely after-sales service, spare parts and can continue to provide services for customers’ whole production circle.

How To Choose Linear Vibrating Screen

How To Choose Linear Vibrating Screen How To Identify Circular and Linear Vibrating Screen

How To Identify Circular and Linear Vibrating Screen Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features 5 Tips of Vibrating Screen Problems & Solutions

5 Tips of Vibrating Screen Problems & Solutions

Dear Sir,

Sub. : Introduction of manufacturer of Crushing, Screening and Feeding Equipment.

We at M/s. Rullitech Engineers are glad to introduce ourselves as one of the leading manufacturers of Crushing, Screening and Feeding Equipments.

Our current Product Range is as under:

A. Jaw Crusher.

i. Single Toggle design ranging up-to size 48” x 40”.

ii. Double Toggle design ranging up-to size 48” x36”.

B. Impact Mills (Non Reversible)

Ranging up-to size 1800 mm Diameter x 1800 mm Length.

C. Hammer Mills (Reversible)

Ranging up-to size 1800 mm Diameter x 2400 mm Length.

D. Horizontal Shaft Impactor.

Ranging up-to size 1600 mm Diameter x1600 mm Length.

E. Double Roll Crusher.

i. Smooth Roll ranging up-to size 1600 mm Diameter x 1600 mm Length.

ii. Tooth Roll ranging up-to size 1200 mm Diameter x 2400 mm Length.

F. Single Roll Crusher

Up-to size 1100 mm Diameter x1200 mm length.

G. Four Roll Crusher.

Ranging up to size 800 mm Diameter x 1000 mm Length.

H. Ring Granulator

Ranging up to size 1400 mm Diameter x 2900 mm Length.

I. Feeder Breakers

J. Flip-Flop Screen.

Ranging up-to size 2500 mm Wide x 8500 mm Length.

K. Circular Motion Vibrating Screen

Ranging up to size 2500mm Wide X 8500 mm Length.

L. Feeders

Apron Feeder: Up to size 1500mm Width

Grizzly Feeder: Ranging up-to size 1500 mm Wide x 6000 mm Length.

Reciprocating Feeders: ranging up-to size 1200 mm Wide x 3000 mm Length.

We also undertake execution of entire crushing, screening and handling system on turnkey basis.

Accordingly, please find attached herewith brochures of our various products for your kind perusal.

If you need any further information with regard to our products, please feel free to contact us

Yours faithfully,

For, Rullitech Engineers

Dear,

This is Taha Atari from Rawaf Holding Company in Saudi Arabia, looking for:

1- Grizzly Screen size 1.5m x 3m

2- Screen 3 deckes size 7m x 3m

3- Small feeder for tunnel

Please if you have the above items send me details with the prices

Regards

Taha Atari

+966562008755

Ok, Mr Taha Atari,

Thanks for your inquiry, we are a vibrating screen manufacturer, and i will contact you for the grizzly screen details.

Extra Heavy Duty Single Bed Banana Vibrating Screens open construction, with 24 hour/day operation time and fixed installation, with thefollowing features:

Dimension: Each screen must be installed in the current existing plant so its Dimensions should not exceed according to plans. See annex “A-1 and A-2”.

Data for the design of each screen: Material: Sodium chloride with a bulk density of maximum 1.28 TM/M3.

Granulometry: See annex “B”

Humidity: Maximum 4.5%

Flow: 600 metric tons per hour.

Openings in screening media: The meshes must be distributed to screen at a minimum flow of 600 tons metric per hour in accordance with the granulometry indicated in Annex “B” and comply with the quality requirements which the fine resulting from screening must be the following: 100% passing ½” mesh, 95% passing 3/8”

Mesh type: Polyurethane modules with 304 S.S. stainless steel wire. Flex Mat 3D 1 ft x 1 ft, (310×310) with variable opening, with pin and bushing fixation.

Support Frame: Designed to accept Flex Mat Panels as screening media, Modular system with reinforcements and rubber coatings resistant to friction and corrosion. The racks (tubular) main beds must be classified for primary bed and articulated to the side walls with Huck type screws, as well as all the supports for Attach Flex Mat panels, side plates, lainers, feed and discharge plates.

Operating speed: 850-915 RPM.

Desired efficiency: 90-100%.

Power: Maximum: 80 HP/59.6 KW. 460volts, 3ph, 60 Hertz, IPW 66 electrical components, TEFC electric motors, with epoxy paint treatment for tropical or severe 2 to 3 µmm thick.

Suspension of each screen: It must be on steel helical springs between the base and the screen (each one). The Four (4) corners that go on a pedestal type base, also have One (1) steel helical spring in axial position at each corner to stabilize the equipment during stops and starts.

Transmission system: The electric motor and transmission preferably by cardan shaft or Flexible coupling.

Vibrating mechanisms: Preferably LOW-HEAD type of movement with spherical role bearings and with counterweights that must be housed inside the mechanism box and be lubricated by oil bath. Mechanisms are synchronized at startup by a cardan shaft preferably or by flexible coupling (not accepted coupling by means of bands between electric motor and mechanism).

Power box: Screwed to the side plates and with 1” thick screwable rubber lainers and hardness of 60 Shore or similar.

Discharge lip: Screwed to the Y side plates with 1” thick screwable rubber lainers and hardness of 60 Shore or similar.

Coatings: All critical parts such as plates and beams that come into contact with the material. They must be covered with material resistant to friction and corrosion.

Back plate: Included.

Side plates and lining: Screwed rubber.

Support frames: Designed to accept Flex Mat Panels as screening media.

Manufacture: All components of the screen must be relieved of stress, thermally and the fully assembled equipment shall be tested in empty for a period of time between 24 to 36 hours, the report of

operation must be delivered along with the operation manuals and maintenance.

Isolation Bases: It must be manufactured in accordance with the dimensions of each screen and without exceeding the maximum dimensions allowed in accordance with the annexed drawing A-1 and A-2 of the plant, it must have all the accessories (springs, shock absorbers and/or base rosta) for the correct operation of the screen and minimize the efforts towards the structure.

Paint: Metal structure and exposed components with cleaning maintenance using sandblasting to obtain a white metal cleaning (SSPC-5, No 1) with 3 to 4 μmm Inorganic Zinc primary coating.

Epoxy Coating (RA-26) from 4 to 5 μm as a bond and Coating Polyurethane (RA-28) as a finish of 3 to 4 μmm thickness in orange color. last two.

Warranty: 12 months in operation on manufacturing and/or workmanship defects.

Additional considerations: For the technical evaluation of the proposed screen, the supplier must submit a Simulation of the performance of the proposed screen with a flow of 600 tons metric per hour and with granulometry data, type of material and humidity provided.

Operation and maintenance manuals must be provided in Spanish, in which the operating parameters in which the equipment is delivered are specified operating as is operating speed, frequency and stoke with the flow of 600 Specified TM/h of each screen.

Shipping charges to Mexico.

I appreciate your answer as soon as possible.

Dear Sir/Madam,

I am Ana Stroilescu, representing the company Tesaro from Romania. Our core competencies extend across many business fields. We are carrying on special projects for private entities as well as state-owned enterprises and public institutions.

We have completed many engineering and also design projects by now. At the moment, we are looking to find some industrial equipments.

We are looking to find a vibrating screen with the following specifications:

Dimensions: 1500 x 4000 mm

Sorting capacity – about 10 tons / hour, with the following structure:

Sort 0-2mm about 48%

2-4mm about 36%

4-8mm about 10%

> 8mm rest 8%

Nr screens: 3

Material: Stainless steel

Mesh size: 2mm, 4mm, 8mm

Electrically operated motor: approx. 15kW

Processing capacity: 50-100 to / h

Can you please let me know if you can help us find the suitable machine?

Kind regards,

Ana Maria Stroilescu

yes sir, We have various models of vibrating screens to meet your needs

We are involved in EPC industrial project in a fertilizer plant, we need vibrating screens for the screening station. Do you have references for screens walking ( MAP,TSP and DAP) , especially 2400 t/h or 1200 t/h.

please find attached the technical specs.

would you send us your proposal accordignly.

waiting for your feedback asp

Hello, my name is Oscar Rodriguez and I need a quote for the Assy excitation system for a 3-deck screen of 1800 mm wide x 4800 mm long.

Thank you for your inquiry, we will contact you and send you more about the vibrating screen

Vibrating screen for hbi plant.. Above 700 degree for hot application..

Which vibrating screen to be used.. It’s know how or it’s manufactures.. It’s for hbi plant…

Thanks..

I am looking for a fabricator or manufacturer for a river sand vibro machine with a capacity of 120 metric tons per hour and 300 metric tons per hour, would that be you?

Yes Mr Jose Ragadio,

I will ask the manufacturer to contact you, thanks for your inquiry

I need mini size vibrator machine. .

Do whatapp me 7548982415