6 Hot Types Speed Reducer [Advantages & Disadvantage]

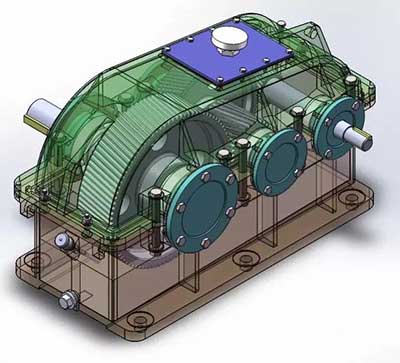

Speed reducer is an independent component composed of gear transmission, worm transmission and gear worm transmission enclosed in a rigid shell. The reducer plays the role of matching speed and transmitting torque between the prime mover and the working machine or actuator. It is often used as the deceleration transmission device between the prime mover and the working machine.

The speed reducer is mainly used for transmission machines with low speed and high torque. The motor, internal combustion engine or other high-speed power is meshed with the large gear on the output shaft through the gear with less teeth on the input shaft of the reducer to achieve the purpose of deceleration.

- Conveying Equipment: conveyor belts, screw conveyors, bucket elevators, etc. Reduction gears are used to control the conveying speed and torque of materials.

- Lifting Equipment: cranes, overhead cranes, hoists, etc. Reduction gears provide stable torque output and precise position control.

- Industrial Machinery: machine tools, printing presses, packaging machines, metallurgical equipment, chemical equipment, etc. Reduction gears are used to reduce the speed of the input shaft and provide the required torque. output.

There are many kinds of speed reducers with various uses. The following is an introduction to the types of speed reducers:

- According to the transmission type: gear speed reducer, worm speed reducer and planetary gear speed reducer.

- According to the transmission stage: single-stage and multi-stage speed reducer.

- According to the gear shape: cylindrical gear speed reducer, conical gear speed reducer and conical cylindrical gear speed reducer.

- According to the layout of transmission: deployable, split and coaxial speed reducer.

Single Stage Cylindrical Gear Speed Reducer

Single stage cylindrical gear reducer is suitable for reduction ratio of 3 ~ 5. The gear teeth can be straight teeth, oblique teeth or herringbone teeth. The box body is usually cast with cast iron or welded with steel plate. Rolling bearings are commonly used in bearings. Sliding bearings are only used when heavy load or ultra-high speed.

Double Stage Cylindrical Gear Speed Reducer

The two-stage cylindrical gear reducer is divided into three types: unfolded type, split type and coaxial type, and the applicable reduction ratio is 8 ~ 40.

- Deployable Type: due to the asymmetric arrangement of the gear relative to the bearing, the stiffness of the shaft is required to be large, and the torque input and output ends are far away from the gear, so as to reduce the uneven distribution of load along the tooth width caused by the bending deformation of the shaft. Simple structure, the most widely used.

- Split Type: because the gear is symmetrically arranged relative to the bearing, the bearing force of the gear and shaft is more uniform. In order to reduce the total axial force on the shaft, the helix direction of the two pairs of gears should be opposite. The structure is complex and is often used in places with high power and variable load.

- Coaxial Type: the axial dimension of the reducer is large, the intermediate shaft is long and the stiffness is poor. When the oil immersion depth of the two large gears is similar, the bearing capacity of the high-speed gear can not be brought into full play. It is often used in places where the input and output shafts are coaxial.

Single Stage Bevel Gear Speed Reducer

Single stage bevel gear speed reducer is applicable to the reduction ratio of 2 ~ 4. The transmission ratio should not be too large to reduce the size of bevel gear and facilitate processing. Only used in drives where two axes intersect vertically.

Conical Cylindrical Gear Speed Reducer

Conical cylindrical gear reducer is suitable for reduction ratio of 8 ~ 15. The bevel gear shall be arranged at the high-speed stage to reduce the size of the bevel gear. Bevel gears can be straight teeth or curved teeth. Cylindrical gears are mostly helical teeth, which can offset part of the axial force of bevel gears.

Worm Speed Reducer

Worm speed reducer mainly includes cylindrical worm speed reducer, circular arc toroidal worm speed reducer, conical worm speed reducer and worm gear speed reducer, among which cylindrical worm speed reducer is the most commonly used.

Worm speed reducer is suitable for reduction ratio of 10 ~ 80. Compact structure, large transmission ratio, but low transmission efficiency. It is suitable for working with low power and clearance. When the circumferential speed V of the worm is ≤ 4 ~ 5m / s, the worm is of the lower type, and the lubrication and cooling conditions are good; When v ≥ 4 ~ 5m / s, the worm is top mounted, and the stirring loss of oil is large.

Planetary Gear Speed Reducer

Due to the structure of planetary gear speed reducer, the minimum single-stage reduction is 3 and the maximum is no more than 10. The common reduction ratio is 3 / 4 / 5 / 6 / 8 / 10, and the number of reducer stages is generally no more than 3.

Compared with other reducers, planetary gear speed reducers have the characteristics of high rigidity, high precision, high transmission efficiency, high torque, high volume ratio and lifelong maintenance free.

Coal [Components, Types, Uses] | Advantage & Disadvantage of Coal

Coal [Components, Types, Uses] | Advantage & Disadvantage of Coal 11 Common Faults of Sand Washer and Solutions

11 Common Faults of Sand Washer and Solutions 14 Types of Ball Mill Troubleshooting and Solutions

14 Types of Ball Mill Troubleshooting and Solutions How to improve The Excavator Bucket Teeth Service Life

How to improve The Excavator Bucket Teeth Service Life