Hot 20 Types Mineral Separation Machine [Principle GIF]

Mineral separation machines are mechanical equipments used in the mineral beneficiation process, mainly based on the differences in physical, physicochemical or chemical properties of different minerals in the ore, using various methods to separate different minerals and obtain useful minerals.

According to the beneficiation process, separator machines can be divided into crushing, grinding, screening, separating, and dewatering equipments. The separating machinery is divided into gravity separator, magnetic separator, flotation machine, and special separation machinery according to their working principles.

In this article, visual animations are used to demonstrate the working principles of mineral separation machines such as color sorters, ore washing machines, cyclones, jigger, shaking table, magnetic separator and iron removers etc.

1. Color Sorter

Color sorter is a device that utilizes the principle of photoelectric technology to detect and separate abnormal colors and foreign impurities from a large number of bulk products. The color sorter has a simple structure, convenient assembly, and low failure rate.

2. Spiral Classifier

The spiral classifier is mainly used for classifying and washing grinding products. It is a mechanical classification equipment that utilizes the principle that the specific gravity of solid particles varies, resulting in different sedimentation rates in liquids.

3. Double Spiral Ore Washer

Double spiral ore washer is a mechanical equipment used in mineral processing plants, mainly used for cleaning ores, removing dirt and impurities on the surface of ores, and improving the grade and purity of ores.

4. Vibrating Screen

Crushed materials with different particle sizes are divided into several different levels by passing through a single-layer or multi-layer sieve surface of vibrating screen with uniformly distributed holes multiple times.

5. Cylindrical Ore Washer

The cylindrical ore washer is widely used for various difficult to wash large ores, and there are two types of washing machines: cylindrical and cylindrical with screening strips. The latter can divide the washed material into 2 levels of products:+40mm and -40mm.

6. Moving jigger

Moving jigger is used for mineral separation and enrichment in mineral processing plants. This jig machine utilizes the principle of vertical reciprocating motion of the sieve, allowing materials to jump and separate on their own within the sieve, achieving mineral separation of different particle sizes and densities.

7. Single layer Shaking Table

Shaker table is a widely used equipment for gravity separation and mineral processing. It uses mechanical shaking and water flushing to separate ore particles according to density.

8. Suspended Multi-layer Shaking Table

Multi layer shaker table refers to a shaker with two or more layers, which can handle medium to fine particle materials, has high separation accuracy, and further improves space utilization.

9. Hydrocyclone

Hydrocyclone is a classification equipment that uses centrifugal force to accelerate the settling of ore particles, mainly used in the classification equipment of the second stage closed circuit grinding.

The working principle of a hydrocyclone is to apply pressure to the ore and rotate the slurry in a tangential direction into a cylinder, generating high-speed rotation and centrifugal acceleration along the wall of the cylinder. Under the action of centrifugal force, high-density ore particles are thrown towards the wall of the cylinder and slide down to the bottom flow port for discharge, while less dense ore particles move towards the center of the cylinder and are discharged from the overflow port.

10. Heavy Medium Cyclone

A heavy medium cyclone is a coal preparation equipment with a simple structure and no moving parts. It has the characteristics of high sorting efficiency, strong processing capacity, and good sorting effect on difficult or extremely difficult to select raw coal.

The main working principle of the heavy medium cyclone is to use the high-density heavy medium suspension under the centrifugal force to divide the raw coal into clean coal, middling coal and gangue according to the density in the heavy medium cyclone.

11. Fixed Suspended Iron Remover Machine

A suspended iron remover is a DC excited iron removal device used to suspend above a conveyor belt to remove impurities from moving loose materials.

12. Belt Mounted Suspension Iron Remover

When the material passes under the belt suspension iron remover, the ferromagnetic substances mixed in the material are adsorbed on the scrap iron belt under the strong magnetic attraction, and are brought to the edge of the magnetic system. They are thrown into the iron collection box by the inertia and gravity of the ferromagnetic substances, thereby achieving the goal of automatically and continuously eliminating the ferromagnetic substances in the material.

13. Magnetic Pulley

Magnetic pulleys are mainly used to separate iron impurities in mineral belt conveyors. It usually consists of a magnetic system, rotating parts, and supporting parts.

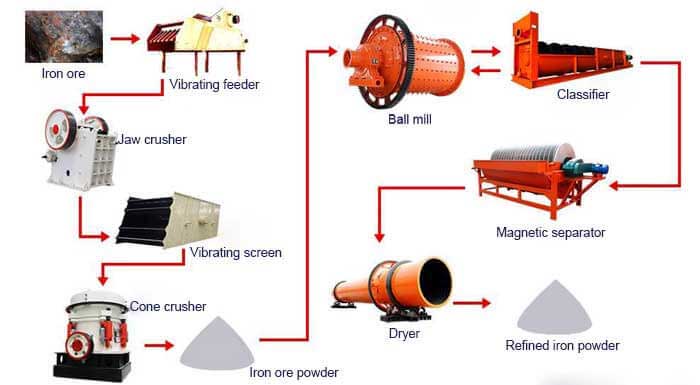

14. Dry Drum Magnetic Separator

A dry drum magnetic separator is a magnetic beneficiation machine designed for sorting dry magnetic minerals. Compared to a wet magnetic separator, which uses liquid as a diluent to improve sorting efficiency, a dry magnetic separator requires the sorted minerals to be dry, and particles can move freely and form independent free states, otherwise it will affect the magnetic separation effect.

15. Downstream Magnetic Separator

A downstream magnetic separator refers to a magnetic separator with the same direction of rotation as the magnetic system and the tank body. Its characteristic is its large processing capacity, suitable for rough selection and selection of strong magnetic materials with coarser particle size, and can also be operated in series with multiple machines.

When the feeding amount is large, magnetic ore particles are prone to loss from tailings, so it is necessary to strengthen operational management and control lower slurry levels.

16. Countercurrent Magnetic Separator

A countercurrent magnetic separator is a magnetic separator with a magnetic system and a tank rotating in the opposite direction. The countercurrent magnetic separator is suitable for rough and sweeping operations of fine-grained strong magnetic minerals, with a high recovery rate but a low concentrate grade.

Due to the tendency of coarse-grained materials to deposit and block the selection space, countercurrent magnetic separators are not suitable for processing coarse-grained materials.

17. Semi Counter Current Magnetic Separator

A semi counter current magnetic separator is a type of magnetic separator that falls between the downstream type and counter current types. Its working principle and characteristics are as follows:

The semi counter current magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of less than 3mm. It is also used for iron removal of coal, non-metallic ore, building materials and other materials.

18. Flotation Machine

Flotation machine is the abbreviation for floating ore dressing machine. In the flotation machine, the slurry treated with reagents is stirred and aerated to selectively fix certain ore particles on the bubbles; It floats to the pulp surface and is scraped out to form foam products, while the rest is retained in the pulp to achieve the purpose of separating minerals.

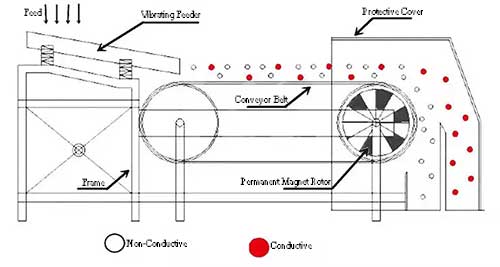

19. Eddy Current Separator

Eddy current separator is an effective metal recovery method for 2mm ² Continuously recover non-ferrous metals such as copper, aluminum, and zinc from the above granular and block solid waste materials.

During the operation of the eddy current separator, a high-frequency alternating strong magnetic field is generated on the surface of the sorting magnetic roller. When conductive non-ferrous metals pass through a magnetic field, eddy currents are induced inside the non-ferrous metals. This eddy current itself generates a magnetic field opposite to the original magnetic field direction, exerting a strong repulsive force on the non-ferrous metals, ejecting them from the material and achieving the purpose of separation.

20. Spiral Chute

Spiral chute is mainly composed of feeding chute, spiral chute, intercepting chute, gathering hopper, and chute support. It utilizes the rotational motion of the spiral groove to form a vortex in the slurry, while being subjected to centrifugal force and gravity, causing the slurry to move downwards along the spiral groove and stratify according to the differences in specific gravity and particle size. Different levels of mineral particles are intercepted by the intercepting groove during their movement and collected separately.

Spiral chutes are suitable for processing various types of ores with different properties, such as metals, non-metals, etc. Its advantages lie in its simple structure, large processing capacity, convenient operation, and strong adaptability to ores. It can be used for the separation of coarse, medium, and fine ores.

Eddy Current Separator & Types | Versus Electrostatic Separation

Eddy Current Separator & Types | Versus Electrostatic Separation Magnetic Minerals | How To Classify Magnetic Minerals

Magnetic Minerals | How To Classify Magnetic Minerals How To Classify Magnetic Separators

How To Classify Magnetic Separators Jig Machine | 4 Types of Jigger Machine|How To Choose

Jig Machine | 4 Types of Jigger Machine|How To Choose