How To Classify Magnetic Separators

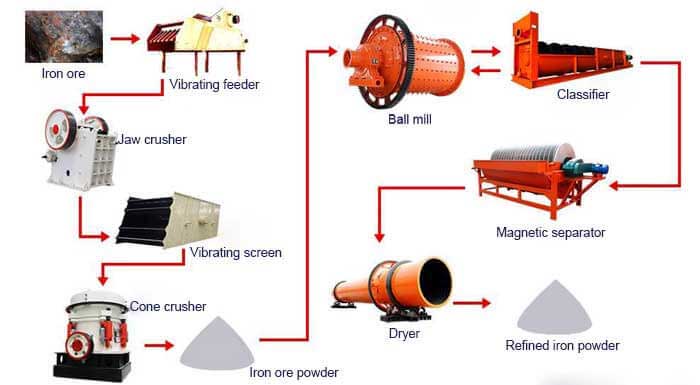

Magnetic separators are commonly used magnetic separation equipment in mineral processing plants. There are many types of magnetic separators, and different magnetic separators have different strengths, sorting media, and beneficiation methods. Understanding the classification of magnetic separators helps us choose the appropriate magnetic separator based on the type of ore.

(1) Types On Basis of Magnetic Field Intensity

① Weak Magnetic Separator. The magnetic field strength on the surface of the magnetic pole is used to separate highly magnetic ores.

② Strong Magnetic Separator. The magnetic field strength on the surface of the magnetic pole is used to separate weakly magnetic ores.

(2) Types On Basis of Sorting Medium

① Dry Magnetic Separator. In air separation, it is mainly used to separate large and coarse sized strong magnetic ores and fine and weak magnetic ores.

② Wet Magnetic Separator. Sorting in water or magnetic liquids is mainly used to separate fine-grained strong magnetic ores and fine-grained weak magnetic ores.

(3) Types On Basis of Selection Method

① Suction Type Magnetic Separator. The selected material is placed at a certain distance from the working magnetic pole or transportation component, and magnetic particles are sucked out of the material before being sucked onto the surface of the working magnetic pole or transportation component after a certain period of time. This type of magnetic separator generally has good concentrate quality.

② Grip Type Magnetic Separator. The selected material is directly fed to the surface of the working magnetic pole or transportation component, and magnetic ore particles are attracted to the surface of the working magnetic pole or transportation component. This type of magnetic separator generally has a higher recovery rate.

③ Attractive Type Magnetic Separator. The selected material is placed at a certain distance from the surface of the working magnetic pole, and the active mineral particles are attracted to the surrounding area of the working magnetic pole surface, and are discharged into magnetic products under their own gravity.

(4) Classification Based On Mineral Particles Movement

① Parallel Flow Magnetic Separator. The direction of motion of the selected material and non magnetic ore particles is the same, while magnetic ore particles deviate from this direction of motion.

② Countercurrent Magnetic Separator. The direction of motion of the selected material and non magnetic ore particles is the same, while the direction of motion of magnetic products is opposite to this direction.

③ Semi Countercurrent Magnetic Separator. The selected material is fed from below, while the movement direction of magnetic and non magnetic particles is opposite.

(5) Types On Basis of Particle Behavior

① A Magnetic Separator with Magnetic Flipping Effect. In this type of magnetic separator, the magnetic chain composed of magnetic ore particles is partially or completely broken during its movement, which is beneficial for improving the quality of the concentrate.

② A Magnetic Separator without Magnetic Flipping Effect. In this type of magnetic separator, the magnetic linkage is not damaged, which is beneficial for improving the recovery rate

(6) Magnetic Separator Types On Basis of Structure

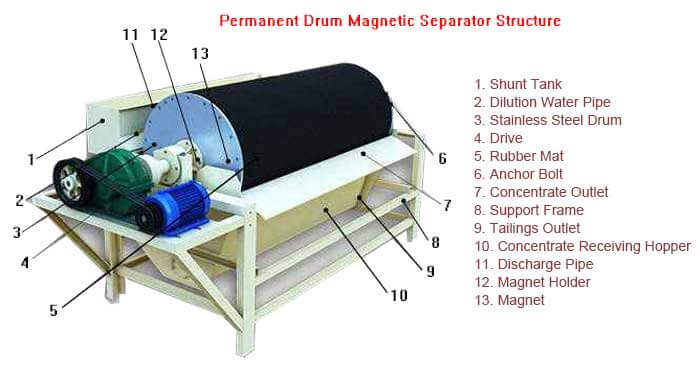

① Cylindrical Magnetic Separator: The design of a cylindrical magnetic separator is based on its magnetic separation function structure, which is mostly weak and medium magnetic field magnetic separators. It has a cylinder on the outside to protect the internal magnetic system. Magnetic materials are subjected to magnetic force within the cylinder, thereby achieving separation from non magnetic materials.

② Cone Type Magnetic Separator: The structural feature of a cone type magnetic separator is that its magnetic field shape is conical. This shape allows the material to receive a more uniform magnetic force in the magnetic field, which helps to improve the efficiency of sorting.

③ Belt Magnetic Separator: In a belt magnetic separator, magnetic materials are transported through a belt to an uneven magnetic field. The magnetic induction pole absorbs magnetic particles from the belt and continuously moves to the second magnetic system, forming a continuous discharge of magnetic minerals. This magnetic separator is suitable for continuous and large-scale production processes.

④ Roller Magnetic Separator: The magnetic separation working surface of the roller magnetic separator is completed on a circular roller with a belt structure. It mainly includes induction roller magnetic separators that generate external magnetic fields and permanent magnet roller magnetic separators that generate their own magnetic fields. When the material passes through the roller, the magnetic material is adsorbed on the roller, thus achieving separation.

⑤ Disk Magnetic Separator: The magnetic materials of the disk magnetic separator are sorted in the sorting disc. It adopts advanced magnetic field design, allowing for sufficient separation of materials in the tray. The disc magnetic separator is suitable for processing materials with finer particle sizes.

⑥ Ring Magnetic Separator: The magnetic separation medium of the ring magnetic separator is installed in a ring structure. It is developed on the basis of disc magnetic separators, and its working principle is similar to that of disc magnetic separators, but its structure is more compact and its efficiency is also higher.

(7) Classification Based On Magnetic Field Type

① Constant Magnetic Field Magnetic Separator. The magnetic source of the magnetic separator is a permanent magnet, a DC electromagnet, or a solenoid coil. The magnitude and direction of magnetic field strength do not change over time.

② Rotating Magnetic Field Separator. The magnetic source of the magnetic separator is a permanent magnet with alternating polarity, which rotates rapidly around its axis. The magnitude and direction of the magnetic field intensity change over time.

③ Alternating Magnetic Field Magnetic Separator. The magnetic source of the magnetic separator is an AC electromagnet. The magnitude and direction of the magnetic field intensity change at any time.

④ Pulsating Magnetic Field Magnetic Separator. The magnetic source of the magnetic inversion machine is an electromagnet that is simultaneously energized with direct current and alternating current. The magnitude of the magnetic field intensity changes over time, and the direction does not change.

(8) Classification Based On Magnetic Field Generation Methods

① Permanent Magnetic Separator: Using permanent magnetic materials such as ferrite, neodymium iron boron, etc. to generate a working magnetic field. Its structure is simple and convenient to use. However, the magnetic field strength is limited, and the beneficiation efficiency and processing capacity are relatively low.

② Electromagnetic Magnetic Separator: uses an electromagnet to generate a magnetic field, and adjusts the magnetic field strength through current. Compared with permanent magnet magnetic separators, electromagnetic magnetic separators have a higher magnetic field intensity, mineral processing efficiency, and processing capacity. But external power supply is required, and the current needs to be controlled during use to maintain a stable magnetic field strength.

③ Superconducting Magnetic Separator: uses the strong magnetic field generated by superconducting materials at low temperatures for magnetic separation. The superconducting magnetic separator has extremely high magnetic field strength and gradient, which can achieve efficient ore separation. At present, superconducting magnetic separators have been applied in laboratories and small-scale production, but they still face some challenges in large-scale industrial applications.

Magnetic Minerals | How To Classify Magnetic Minerals

Magnetic Minerals | How To Classify Magnetic Minerals What is Permanent Magnetic Drum Separator | How Does It Work

What is Permanent Magnetic Drum Separator | How Does It Work Eddy Current Separator & Types | Versus Electrostatic Separation

Eddy Current Separator & Types | Versus Electrostatic Separation Hot 20 Types Mineral Separation Machine [Principle GIF]

Hot 20 Types Mineral Separation Machine [Principle GIF]