Dewatering Equipments for Mineral & Sludge

Dewatering equipments for mineral & sludge play an important role in the follow-up stage of mineral process. After dewatering treatment, mineral products or sludge will reduce moisture content, minimising storage space and decreasing transportation costs. In addition, the removed water can be recycled for reusing.

According to different dewatering methods, dewatering equipments can be divided into the following types:

Each types of dewatering equipments are designed with different structures and working principle, that is suitable for different materials. in this article, will introduct 11 types most popular dewatering equipments that designed for mineral and sludge dewatering:

1. Bucket Elevators

Bucket elevators are a series of hoppers fixed on the endless traction component, which can lift materials vertically and continuously. It can be divided into three types: ring chain, plate chain and belt.

Bucket elevators are commonly used in the front of the production line to transport materials. In fact, the bucket elevator can also be used for the dehydration of coarse particles, and the water flows out under the action of gravity with the rise of materials.

2. Plate and Frame Filter Press

There are 2 types of plate and frame filter press: plate and frame filter press and concave plate and frame filter press. The main difference between them is the structure of the filter chambers.

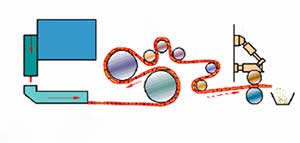

3. Belt Filter Press

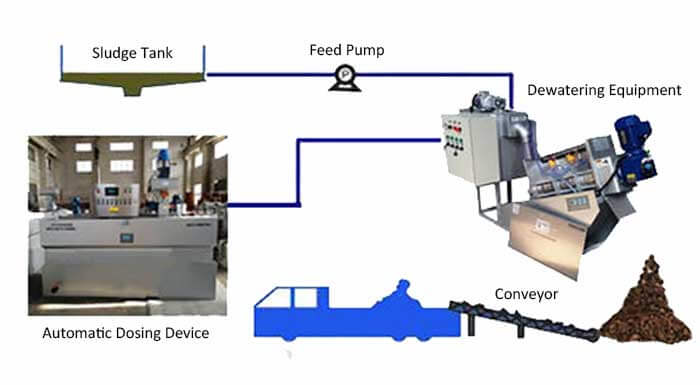

Belt filter press is composed of two tensioned filter belts, which carry the sludge layer and pass through a series of regularly arranged rollers in the shape of S, depending on the tension of the filter belt itself, it forms the pressing and shearing force on the sludge layer, extrudes the capillary water in the sludge layer, and obtains the sludge cake with high solid content, so as to realize the sludge dewatering.

4. Diaphragm Filter Press

Diaphragm filter press is improved on the basis of the structure of the chamber filter press, which increases the dewatering function.

Diaphragm filter press can simultaneously carry out the primary filtration dehydration of high pressure fluid feed, the secondary extrusion dehydration of filter cake and the tertiary dehydration of filter cake blown by strong air flow of compressed air.

5. Rotary Vacuum Filter

Rotary drum vacuum filter is a kind of continuous operation filtering equipment. The main body of the equipment is a horizontal cylinder that can rotate. The surface of the cylinder is perforated metal plate or wire mesh. The mesh is covered with filter cloth. The suspension is in contact with the cylinder at cylinder bottom.

6. Centrifuge (Horizontal Screw Centrifuge)

Centrifuge is used for solid-liquid separation by centrifugal force, It is mainly used for dewatering, concentration, separation, clarification, purification and solid particle classification.

Horizontal screw centrifuge is a kind of continuous dewatering equipment, which uses centrifugal sedimentation to separate materials with different specific gravity, and can continuously feed, separate, wash and discharge materials.

7. Ceramic Vacuum Filter

Ceramic vacuum filter is a new type of efficient and energy-saving filtration equipment, which integrates electromechanical, microporous ceramic and ultrasonic technology, and realizes dewatering by means of vacuum suction and capillary action.

8. Paste Thickener

Paste thickener is a kind of continuous concentration and clarification equipment, which is suitable for concentrate and tailing dehydration of concentrator, and widely used in metallurgy, chemical industry, coal, non-metal beneficiation, environmental protection and other industries.

9. Linear Vibratory Screen

The materials are feed on the linear vibratory screen, and moves forward in a straight line at the same time. The material enters the feed port of the screens evenly from the feeder, and several specifications of upper and lower materials are generated through the multi-layer screens, and part moisture can be removed during the vibration process.

10. Dewatering screen

The main functions of dewatering screen are dewatering, desliming and desedifying, which can be used for sand washing in sand and stone plant, slime recovery in coal preparation plant, tailings dry discharge in ore dressing plant, etc.

11. Mineral Dryer

Mineral dryer is generally rotary cylinder type, which is used to dry materials with certain moisture or particle size, such as iron ore, titanium ore, quartz sand and other minerals.

The dryer cylinder is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, which is in countercurrent contact with the material.

A paddle board is installed on the inner wall of the cylinder, which is used to lift and lower the material, increase the contact surface between the material and the air flow, so as to improve the drying rate and promote the material forward.

Sludge, Sludge Dewatering, Why & How To Dewater Sludge

Sludge, Sludge Dewatering, Why & How To Dewater Sludge Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features Become More Professional In Dewatering Screen

Become More Professional In Dewatering Screen 6 Sludge Treatment Processes and Technologies | Cmparative & Analysis Report

6 Sludge Treatment Processes and Technologies | Cmparative & Analysis Report