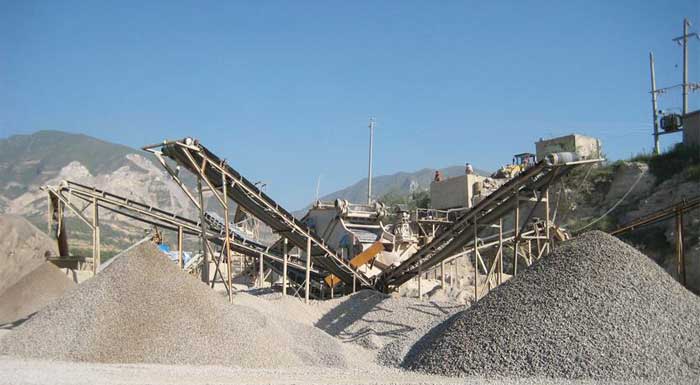

5 Types Crusher Equipments For Sand And Aggregate Production Line

Crusher equipment can be divided into 2 categories according to its working principle:

- Extrusion crusher equipments, such as jaw crusher, rotary crusher, cone crusher, etc. It is suitable for crushing raw materials with a high abrasion index. The content of stone powder in products is low, but generally, the crushed materials have many needle-like particles and poor pumping performance.

- Impact crusher equipments, such as impact crusher and vertical shaft impact crusher. Its characteristics are large material crushing ratio, simple structure, convenient maintenance of equipment, good product granularity and low loss of material compressive strength.

In the large sand aggregate production line, jaw crusher or rotary crusher is usually used for rough breaking, while cone crusher, counterattack crusher or hammer crusher are used for medium breaking.

The common crushers used in sand aggregate production line, their advantages, disadvantages and application scope are as follows:

1. Jaw Crusher

Advantages: simple structure, reliable operation, small size, lightweight, low configuration height, large inlet and outlet, adjustable discharge and outlet, low price;

Disadvantage: Lining plate wear fast, product grain shape is not good, needle sheet shape is more, low output, need to be forced feeding;

Scope of application: Rock hardness adaptability is good, generally used for crushing raw materials, medium crushing equipment needs to be miniaturized.

2. Gyratory Crusher

Advantages: large single processing capacity, low unit energy consumption, good product granularity, large and medium-sized machine can continuously feed, without feeding machine;

Disadvantages: complex structure, large size, high body, difficult maintenance, high price, small feed size, large amount of civil construction;

Scope of application: Applicable to all kinds of hardness rocks, generally used as crushing equipment, small machines can also be used in crushing links.

3. Cone Crusher

Advantages: reliable operation, high output, uniform particle size, small liner wear;

Disadvantages: complex structure, high maintenance requirements, high body installation size, high price;

Scope of application: Rock hardness adaptability, aggregate production line is the most commonly used medium or fine crushing equipment.

4. Counter-Impact Crusher

Advantages: large crushing ratio, fine product, good particle shape, low energy consumption, simple structure;

Disadvantages: Hammer and liner are easy to wear and tear, and the workload of replacement and maintenance is large; dust is serious, not suitable for crushing plastic and viscous materials;

Scope of application: It is suitable for crushing medium-hard rock, medium crushing and sand making equipment. At present, some large-scale equipment is also used for crushing.

5. Hammer Crusher

Advantages: large crushing ratio, high output, good product shape, more fine materials;

Disadvantages: Hammerhead damaged quickly, need to be replaced frequently, work dust, water content of raw materials is more than 12%, viscous materials can not pass effectively;

Scope of application: It is suitable for crushing medium-hard rock, generally used for fine crushing equipment, and used for sand making when there are grates, which has been less used at present.

1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line Four Steps To Build Aggregate Production line

Four Steps To Build Aggregate Production line 6 Types Sandstone Aggregate Screening Equipments

6 Types Sandstone Aggregate Screening Equipments 3 Million Granite Sand Making Production Line

3 Million Granite Sand Making Production Line

Do you have a crusher that can crush limestone from 100mm to 3mm and a crusher that can crusher sand/limestone from 3mm to 0.5mm?

yes sir, we will contact you very soon!

We are interested in the best option to crush sand mixed with small rocks of about 20-50mm to produce fine sand of 3-5mm. in large volumes of thousands of tons. what would be the most suitable type of crusher?