5 Tips for Jaw Crusher Operation

Jaw crusher is widely used in mining industry because of its simple structure, reliable work, convenient maintenance and low production cost. Correct operation and maintenance are beneficial to the improvement of the production capacity of jaw crusher. In this article you will learn 5 tips that should be paid attention to in the operation of jaw crushers.

1. Preparation Before Startup

- Check whether the main parts of the jaw crusher are in good condition, whether the fastening bolts and other connectors are loose, and whether the safety device is complete.

- Check whether the feeding equipment, conveying equipment and electrical equipment are in good condition.

- Check that the lubrication device is in good condition and that the cooling water pipe valve is open.

2. How To Startup and Operation

- Start according to the operation rules, that is, the start-up sequence is the reverse production process;

- When starting the main motor, we should pay attention to the indication of the ammeter on the control cabinet. After 20s-30s, the current will drop to the normal working current value;

- Adjusting and controlling the feeding so that the feeding is uniform, and the particle size of the material ≤ 80%-90% of jaw crusher feed width;

- The temperature of sliding bearing should ≤ 60 ℃, and the temperature of rolling bearing should ≤ 70 ℃;

- If the electrical equipment is automatically tripped, it is strictly forbidden to start forcibly and continuously;

- If a failure occurs, the machine should be shut down immediately.

3. How To Stop

- The stop order of the production line is opposite to the start-up order, that is, it operates in the direction of the production process;

- The work of the lubrication and cooling system can only be stopped after the crusher has stopped, and the circulating cooling water in the bearing should be released in winter. Prevent the bearing from being frozen and cracked;

- Clean up and check all parts of the machine after shutdown.

4. How To lubricate

The connecting rod bearings, eccentric shaft bearings and thrust plate elbows of the jaw crusher need to be lubricated with lubricating oil.

- 1. Lubricate the friction surface in time to ensure the normal operation of the jaw crusher and prolong the service life of the equipment.

- 2. The grease used is general lithium grease or compound calcium grease, or the grease required by jaw crusher manufacturers.

- 3. The grease added into the bearing housing is about 50% of its volume, and clean gasoline or kerosene is used to clean the raceway of the ball bearing when changing the oil.

- 4. An appropriate amount of grease should be injected between the elbow plate and the elbow seat.

5. How To Inspect and Maintain

The inspection and maintenance of jaw crusher mainly include the following:

- 1. Check the heating condition of the bearing. Because the bearing alloy used for casting the bearing bush can only work normally when the temperature is below 100 ℃, if it exceeds this temperature, it should be stopped immediately to check and troubleshoot.

- 2. Check whether the lubrication system is working properly, check the oil quantity in the fuel tank and whether there is oil leakage in the lubrication system. If the oil quantity is not enough, it should be replenished in time.

- 3. Check whether the oil coming back from the return tubing contains metal dust and other dirt. If so, you should immediately stop the machine and open the bearing and other lubrication parts to check.

- 4. Check whether the bolts, flywheel keys and other connectors are loose.

- 5. Check the wear of jaw plate and transmission parts, whether there are cracks in the pull rod spring and whether the work is normal.

- 6. Keep the jaw crusher clean, prevent sundries from entering the lubrication system to accelerate the wear of the equipment and shorten the life of the equipment.

- 7. Clean the filter of lubricating oil with gasoline regularly. After cleaning, you can not continue to use it until it is completely dried.

- 8. The lubricating oil in the tank needs to be updated regularly because the lubricating oil is exposed to air (oxygen) and affected by heat (the temperature increases by 10 ℃, the oxidation rate is doubled). And the oil is constantly aging and deteriorating due to the infiltration of dust, water or fuel and other reasons, so that the oil loses its lubrication performance.

8 Tips Help To Maintain Cone Crusher

8 Tips Help To Maintain Cone Crusher Vibrating Feeder Installation & Operation & Troubleshooting

Vibrating Feeder Installation & Operation & Troubleshooting 20+ Common Faults of Jaw Crusher with Solutions

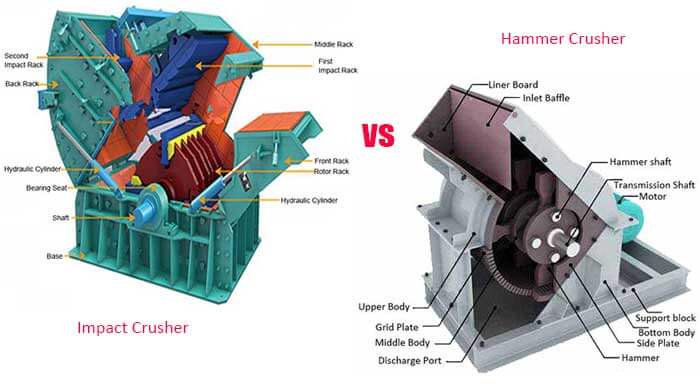

20+ Common Faults of Jaw Crusher with Solutions Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips]

Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips]