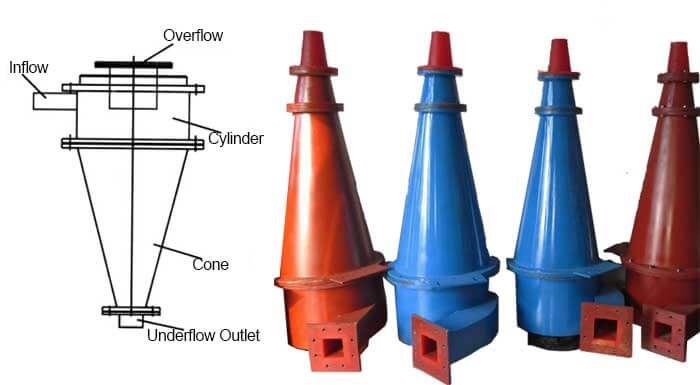

10 + Troubles and Troubleshooting of Hydrocyclones

For hydrocyclones, the troubles that often occur include abnormal super-granularity, failure to reach the cut point, unstable performance, blockage and so on. Below are 10+ troubles about hydrocyclones and the troubleshooting.

Trouble 1: Hydrocyclone Vibration Violently

Troubleshooting

- If empty suction occurs, use the suction pipe.

- Large amount of material, change the feed/hydrocyclone parameters;

- Linear layout, control entrance;

- The overflow pipe is deformed and the overflow pipe is replaced;

- Local blockage in the hydrocyclone, stop and check.

Trouble 2: low Underflow Density

Troubleshooting

- If the hydrocyclone is not fed correctly, replace the discharge nozzle/overflow pipe;

- The size of the discharge nozzle is incorrect, use the correct size discharge nozzle.

Trouble 3: Abnormal Over-Granularity

Troubleshooting:

- Underflow nozzle is worn seriously, so replace the suitable underflow nozzle.

- If the feeding density is too high, check the blockage;

- Feed reverse flow, replace easy-to-grind parts.

Trouble 4: Hydrocyclone Blockage

Troubleshooting

- The mismatched material enters the hydrocyclone and checks the sieve hole.

Trouble 5: Unstable Performance

Troubleshooting

- Uneven distribution of materials, the use of the correct distributor;

- Blockage, check for blockage.

Trouble 6: Cannot Reach Cut Point

Troubleshooting

- The feed size is incorrect, replace the feed/hydrocyclone parameters.

Trouble 7: High Wear Rate

Troubleshooting

- The flow rate is too large-the pressure drops too much, change the feeding condition or hydrocyclone parameters;

- 2-stage operation / need large size hydrocyclone, change hydrocyclone parameters;

- The wearability of the incoming material is high, and the manufacturing material should be replaced.

Trouble 8: Unstable Operating Pressure

Troubleshooting

- The pump and the hydrocyclone are unbalanced, isolate the hydrocyclone to achieve a stable operating pressure or reset the pump speed.

Trouble 9: No Fan Flow is Formed.

Troubleshooting

- large coal amount and foaming coal proportion, reduce the carrying coal;

- Unreasonable pressure setting, adjust pump frequency;

- Feed pump opening small, open the valve;

Trouble 10: Underflow With Too Many Materials

Troubleshooting

- Cut off the solid feed and replace it with a large discharge nozzle;

- Check whether the discharge nozzle and feed pipe are blocked.

Trouble 11: Overflow Occurs

Troubleshooting

- The pipeline of the follow-up system is limited or blocked, and the restriction is cancelled.

- Check the angle of the line and the size of the line in the discharge area.

12 Common Bucket Elevator Troubleshooting

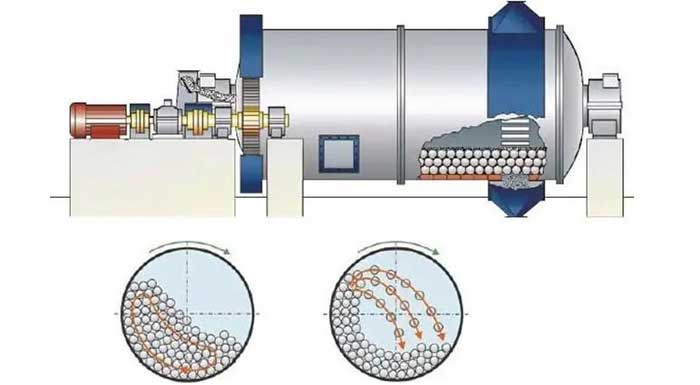

12 Common Bucket Elevator Troubleshooting 14 Types of Ball Mill Troubleshooting and Solutions

14 Types of Ball Mill Troubleshooting and Solutions Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair Vibrating Feeder Installation & Operation & Troubleshooting

Vibrating Feeder Installation & Operation & Troubleshooting

this article was more beneficial to me and i really appreciate it.

but I would like to ask also for the causes of those 10 troubles as a recommendation.

thanks.