What Is Asphalt Concrete | Types & How Is It Made

What Is Asphalt Concrete

Asphalt concrete, also known as bituminous concrete, is a mixture of crushed stone or crushed gravel, stone chips or sand, mineral powder, etc. with a certain proportion of road asphalt materials, mixed under strict control.

Asphalt concrete is usually used for runway, highway, airport, garden road, traffic navigation and many other types of pavement construction.

Asphalt Concrete Advantages

- Compared with ordinary cement concrete, asphalt concrete has better mechanical properties, and the asphalt concrete pavement has better load capacity;

- Asphalt concrete has good elastic and plastic deformation ability and is not easy to be damaged;

- Good adhesion, make the vehicle drive more like safety;

- Shock absorption, faster and more stable driving, and reduce noise;

- Asphalt concrete pavement will not raise dust, so it is easy to clean.

Asphalt Concrete Disadvantages

- Asphalt concrete is easy to break when the vehicle is overloaded seriously;

- The low temperature in winter will also cause the fracture of asphalt concrete pavement;

- When the temperature is high, ruts are easy to be caused by repeated rolling;

- The surface of asphalt concrete is smoother than that of cement concrete, which is easy to cause traffic accidents in rainy days.

Asphalt Concrete Types

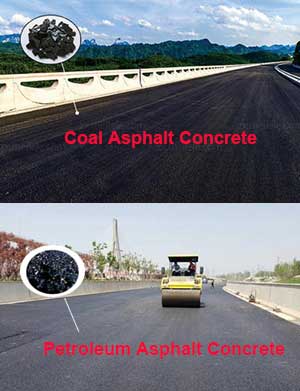

According to the different binders used, asphalt concrete can be divided into petroleum asphalt concrete and coal asphalt concrete;

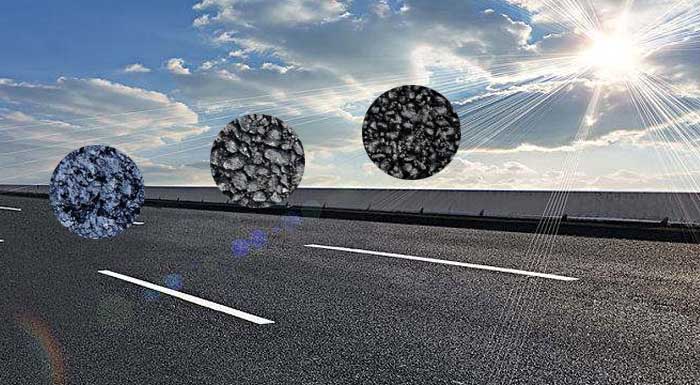

According to the different types of aggregates used, asphalt concrete can be divided into 4 types: macadam asphalt concrete, gravel asphalt concrete, sandy asphalt concrete and slag asphalt concrete, of which macadam asphalt concrete is the most common.

According to the difference of the maximum particle size of the mixture, asphalt concrete can be divided into 4 types: coarse-grained (35-40mm), medium-sized (20-25mm), fine-grained (10-15mm) and sand (5-7mm).

According to the different gradation of mineral aggregate, asphalt concrete can be divided into 3 types: dense graded asphalt concrete, open graded asphalt concrete and gap graded asphalt concrete. Among them, the dense graded macadam mixture of hot mixing and hot paving is durable, high strength and good integrity, which is the most widely used representative material for building high-grade asphalt pavement.

According to the composition of mineral aggregate, asphalt concrete can be divided into dense-suspension structure (AC-Ⅰ), skeleton-void structure (OGFC) and dense-skeleton structure (SMA).

How Asphalt Concrete Is Made

The asphalt concrete mixing station can initially mix cold sand and stone of different specifications through the feeder of cold ore storage and batching device. The mixture is sent to the drying cylinder by the cold material conveyor for drying and discharged from the roller after heating, and then sent to the screening device by the hot material elevator for secondary screening.

The screened sand and stone materials are stored in the heat storage bin, and then they are weighed in the heat material weighing hopper according to the preset proportion. In addition, the hot asphalt stored in the heat preservation tank is pumped to the asphalt weighing bucket by the asphalt delivery pump for weighing; After each material is weighed according to the mix proportion, they are put into the mixer successively according to the procedure. After mixing evenly, they are unloaded into the transport vehicle or sent to the finished product storage bin.

The main equipment of the asphalt concrete mixing plant includes:

- Asphalt Heating Pot

- Steam Boiler

- Ore Powder Bin

- Sand Storage Tan

- Mixer and Weighing Equipment

- Heating Drum

- Asphalt Pump and Pipeline

- Dust Removal Facilities, etc.

Hot Types of Asphalt Pavement | [8 Types & Features]

Hot Types of Asphalt Pavement | [8 Types & Features] Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications]

Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications] Cement VS Concrete [8 Difference Between Cement and Concrete]

Cement VS Concrete [8 Difference Between Cement and Concrete] 5 Concrete Structure Defects [Causes & Prevention & Repair]

5 Concrete Structure Defects [Causes & Prevention & Repair]

thank you very much sir