Industrial Solid Waste Recycling [ Waste Rock ]

Industrial Solid Waste Type

Industrial solid waste can be divided into general industrial waste (such as blast furnace slag, steel slag, red mud, non-ferrous metal slag, fly ash, cinder, sulfuric acid slag, waste gypsum, desulphurization ash, calcium carbide slag, salt mud, etc.) and industrial hazardous solid waste. Among them, the most common is the former, such as waste rock, tailings, slag and so on.

In this article will describes the source, use and processing equipment of waste stone.

Source of Waste Rock

Waste rock refers to the non-ore-bearing surrounding rock and sandwiched stone that has been mined. In the open-pit stope, the stripped overlying soil, surrounding rock and gangue stone without industrial value are generally called waste rock. Waste rock includes two types of stone:

- Exfoliation layer of metal or non-metallic ore or low-grade ore with no mining value.

- Stone in the abandoned mine.

Use of Waste Rock

- Railway Ballast: The requirement of railway ballast is that it is not fragile under vibration pressure. Of course, the rock developed by lamination or bedding is not suitable to be used as road slag, while limestone and basalt are more suitable to be used as railway ballast.

- Raw Materials of Cement: The basic raw materials of cement are limestone and clay ore, while limestone, clay rock and shale are common waste stones in mines. In addition, the waste rock with high content of amorphous materials, such as glassy volcanic rock, tuff, pumice and so on, can also be used as active mixed materials.

- Landfill Potholes: The waste rock is discharged into an open pit that has existed in the past, and then covered with a certain thickness of arable soil to make it arable land. This is the method being adopted by some mines.

- Sand Aggregate: Sand and gravel aggregate is the largest, indispensable and irreplaceable basic material in the construction of infrastructure projects such as buildings, roads and bridges, and a large number of waste rocks are produced in the long-term mining and production process of metal and non-metal mines. These waste rock can be processed into sand and gravel aggregates to save natural resources.

Sand Making From Waste Rock

The commonly used waste stone processing equipment are: jaw crusher, impact crusher, cone crusher, hammer crusher, gyratory crusher, vertical shaft impact crusher, as well as vibrating screen, vibratory feeder, belt conveyor and other auxiliary equipment.

Raw Materials: low-grade limestone and dolomite with a small amount of soil

Production Capacity: 200t/h, 3000t/d (8 hours per day)

Final Products: 0~5mm, 5~10mm, 10~20mm, 20~30mm

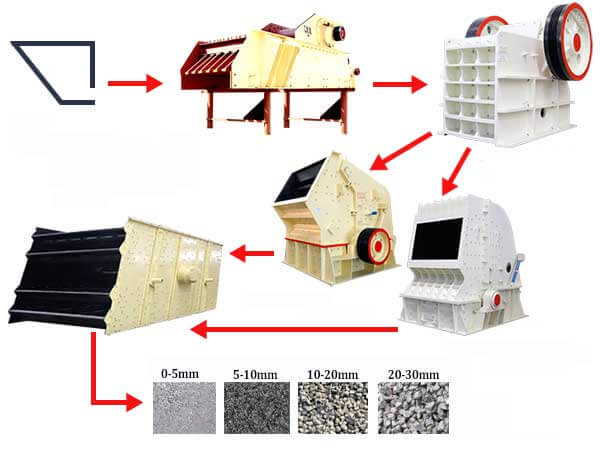

Configuration and Process are as follows:

Waste Rock Processing Flow

Firstly, the coarse crushing is carried out, and the large stone is uniformly sent to the jaw crusher by the vibration feeder through the silo for rough crushing, and the coarse crushed stone is sent by the belt conveyor to the impact crusher for further crushing.

Then carry on the screening, the finely crushed stone is sent to the vibrating screen by the belt conveyor for screening, and several kinds of stones of different specifications are screened out, and the stones that meet the particle size requirements are sent to the finished material pile by the finished belt conveyor, and the stones that do not meet the particle size requirements are returned by the belt conveyor to the impact crusher for re-crushing, forming closed-circuit circulation for many times. For different kinds of ores, different crushing stages can be selected.

Industrial Solid Waste Recycling [ Tailings ]

Industrial Solid Waste Recycling [ Tailings ] Industrial Solid Waste Recycling [ Slag ]

Industrial Solid Waste Recycling [ Slag ] Recycled Aggregate From Construction Waste

Recycled Aggregate From Construction Waste Lithium Battery Recycling and Treatment Methods

Lithium Battery Recycling and Treatment Methods