How To Build A Brick Wall | Standards & Quality & Procedure

Brick Wall Construction Method

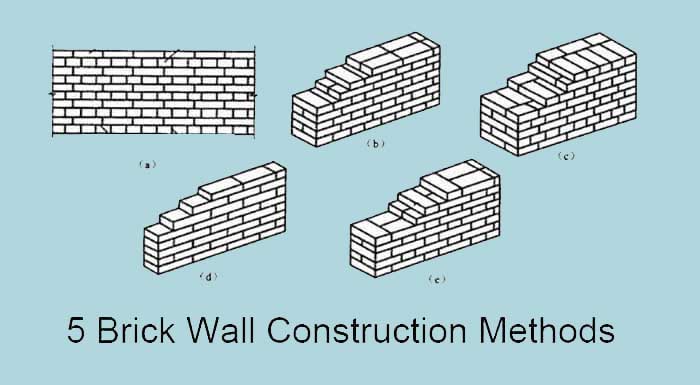

In order to improve the integrity, stability and bearing capacity of brick wall, the arrangement of bricks should follow the principle of staggered upper and lower joints, and avoid the occurrence of vertical through joints. The length of staggered joints or masonry is generally not less than 60 mm.

There are several common ways to build solid brick walls (figure below):

How To Build A Standard & Quality Brick Wall (PDF DOWNLOAD)

Standards of Brick Walls

(1) The variety and strength grade of bricks must meet the design requirements. Bricks should be wetting one day in advance to avoid excessive absorption of moisture in mortar and influence the bonding force.

The moisture content of common burnt clay bricks and hollow bricks should be 10-15%, and that of sand lime bricks and fly ash clay bricks should be 5-8%.(When the depth of immersion around the cross section of the brick is 15-20 mm, it meets the requirements)

(2) Porous bricks should not be used on the ground or below the moisture-proof layer in frost-heaving areas.

(3) When temporary openings are left on the wall, the wall surface at the side-to-side junction should not be less than 500 m m, and the net width of the openings should not exceed 1 m.

(4) Wall or parts that not allow scaffolding holes:

- ① 120 mm thick wall and independent column;

- ② Inter-window wall with width less than 1 m;

- ③ 200 mm on both sides of doors and windows and 450 mm at corners;

- ④ Beam or beam cushion and its range of about 500 mm;

- ⑤ The triangle range of 60 degrees with the beam and the height range of 1/2 of the span of the beam.

(5) If the floor or roof is not built, the allowable free height of the wall or column is shown in the table below. Temporary support shall be adopted when the limit is exceeded.

(6) The top layer of bricks of 240mm thick load-bearing wall should be built with complete bricks.

(7) The top surface of masonry with prefabricated beams and slabs should be leveled and grouted again when installed.

(8) The holes of porous bricks should be built perpendicular to the compressive surface.

(9) Masonry with wall thickness of 370 mm or more should be built by double-sided vertical hanging line.

(10) Transparent joints, blind joints and false joints shall not appear in vertical grey joints.

The filling wall of the frame beam should be built to the bottom of the beam, reserved for 18-20cm, and then obliquely packed with solid bricks after a week or so, so that the mortar is full.

One week interval is to allow the new masonry to complete the wall self-shrinkage. Oblique masonry can reduce the shrinkage of ash joints to prevent cracking at the bottom of beams due to wall shrinkage.

Brick Wall Quality Requirements

Horizontal and vertical, full mortar, uniform grey joints, staggered upper and lower joints, internal and external masonry, steady corners and junctions. The saturation of mortar in horizontal mortar joints of solid brick masonry shall not be less than 80%. The thickness of horizontal joints and the width of vertical joints are stipulated to be 10 ± 2mm.

(1) The mortar plumpness of horizontal grey joints shall not be less than 80%. The bond area between brick bottom and mortar shall be checked by Baige net, and no less than 5 spot checks shall be made in each inspection batch.

(2) The corner of brick masonry and the junction of vertical and horizontal walls should be built at the same time. It is strictly forbidden to separate internal and external walls construction without reliable measures.

(3) In areas with seismic fortification intensity of 6 or 7 degrees, brick walls construction need to be reinforced with wall ties.

(4) The deviation of the axes of brick masonry should not be greater than 10mm, and when the building height >10m, it’s 20mm.

(5) The method of brick masonry construction should be staggered joints and built inside and outside.

(6) The thickness of horizontal grey joints of brick masonry should be 10mm, but not less than 8mm, nor more than 12mm.

Brick Wall Construction Procedure

(1) Mortar mixing: Mortar mixing ratio should adopt weight ratio, cement is (+2%), sand and plaster should be controlled within (+5%). It is suitable to use mechanical mixing. The mixing time is not less than 1.5 minutes.

(2) Brick watering: Clay bricks must be wetting before used. Generally, water is immersed into the four sides of the brick by 1.5cm, and the water content is 10% to 15%.

(3) Bricklaying: You need many tools to build the brick walls.

- Mortar

- Mixing bucket

- Levels

- Plumbs

- Brushs

- Brick jointer

- Club hammer

- Tape measure

(4) Brush and clean the walls: Excess mortar need to be brushed off, you can wipe smears away with a damp sponge, Be sure you wring out your sponges before using them on the wall. You want a damp sponge, not a wet one. Or you will weaken the new brick walls.

Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications]

Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications] What is Brick Masonry | How To Supervise Brick Masonry Construction

What is Brick Masonry | How To Supervise Brick Masonry Construction 5 Concrete Structure Defects [Causes & Prevention & Repair]

5 Concrete Structure Defects [Causes & Prevention & Repair] How Much Does Crush Sand Plant Cost & SetUp Procedure

How Much Does Crush Sand Plant Cost & SetUp Procedure

hammer crusher price

Thanks for share ,please check the ball mill price