How About Artificial Sand Compared With Natural Sand

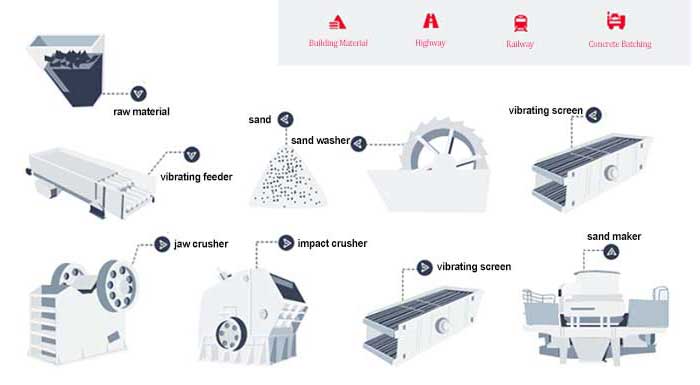

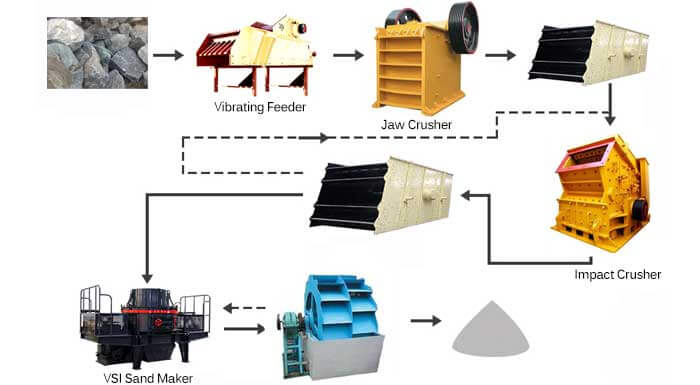

Artificial sand also called manufactured sand or crushed sand, the artificial sand are manufactured by crushing rocks, stones or larger aggregates into small size particles in the quarry.

Recent years, with the decrease of natural sand, the market of artificial sand shows great potential and vitality. And the huge demand of the construction market has promoted the development of the artificial sand market rapidly.

So, how about artificial sand compared with natural sand such as river sand, sea sand and mountain sand? What’s the benefits?

1. Appearance

Artifical sand is a kind of sand material produced by sand-making equipment, such as impact crusher. Compared with natural river sand, artifical sand has the characteristics of sharp edges, many needles and flakes, and rough.

River sand is directly excavated from the river, so it will be mixed with small pebbles and fine sand. These small pebbles are washed by the river for a long time, and the edges and corners are rounder, while the artifical sand produced by sand and gravel equipment is more sharp and distinct, and the firmness is worse than river sand.

2. Ruggedness and Durability

The firmness of artificial sand is slightly worse than that of river sand, and there is no problem in the use of ordinary concrete. But for concrete members, except admixtures, the lime-sand ratio and the content of stone powder should also be controlled.

3. Quantity of Stone Powder

High powder content is an important characteristic of artificial sand, which is different from natural river sand. When distinguishing, we should distinguish the powder content of artificial sand from the sediment content of natural sand.

The sediment content of natural sand refers to that the size of natural sand < 0.075 mm, which is composed of viscous clay and has a large plastic index. It has no connection with the hydrated crystalline stone of cement. Therefore, the sediment content of natural sand directly affects the strength of concrete.

The powder content of manufactured sand refers to the fine rock powder < 0.075 mm. It can not react with cement hydration, but it has excellent relationship with cement crystalline stone and plays a filling effect of micro-aggregate.

In fact, if the powder content of manufactured sand < 20%, it has no adverse effect on the cohesion time and strength development of concrete, but has greatly impaction on the workability, pumpability and strength of concrete mixtures.

4. Adhesiveness and Compression Resistance

The granularity of machine-made sand is irregular. When using cement to bond, it tends to have better bonding, more compressive and longer service life.

5. Composition and Structure

Artificially selected raw materials are uniform and stable in material. Mineral composition and chemical composition are the same as raw materials. They are not as complex as natural sand.

6. Fineness Modulus

For natural sand, one kind of fineness modulus can be graded in many ways. The fineness modulus of machine-made sand can be controlled artificially by production process, and the production can be organized according to user’s requirements, which is impossible for natural sand.

In fact, machine-made sand not only has a wide range of sources, stable material, easy to operate and control, good performance, and can meet the building demand, but also is economically feasible.

It is the development direction of the future construction market, and is also very beneficial to the protection of the natural environment.

6 Tips Help To Make High Quality Artificial Sand

6 Tips Help To Make High Quality Artificial Sand 33 Tips About Artificial Sand You Need To Know

33 Tips About Artificial Sand You Need To Know Why Desert Sand Cannot be Used As Building Materials

Why Desert Sand Cannot be Used As Building Materials VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications