What is Brick Masonry | How To Supervise Brick Masonry Construction

What is Brick Masonry

Brick masonry, an integral material made of brick and mortar, is the most widely used building material at present. According to whether the masonry is reinforced or not, it can be divided into unreinforced brick masonry and reinforced brick masonry.

Unreinforced Brick Masonry

Unreinforced brick masonry is often referred to as brick masonry. Strength indexes include compressive strength, tensile strength, flexural strength and shear strength.

The strength of brick masonry under axial pressure is called compressive strength. The main factors affecting the compressive strength of brick masonry are: the level of brick and mortar, the higher the level, the higher the compressive strength of brick masonry.

Reinforced Brick Masonry

The brick masonry with steel or reinforced concrete is compact and uniform, which improves the bearing capacity of the masonry and enlarges the application scope of the brick masonry. Especially, the application of various types of porous bricks is expanding and developing. It is more superior to configure reinforcement or reinforced concrete in the holes of porous bricks to form reinforced masonry.

According to the reinforcement configuration, the main forms of reinforced brick masonry are transverse reinforced brick masonry, longitudinal reinforced brick masonry and composite brick masonry.

5 Types of Bricks for Brick Masonry Construction

There are different types of brick used for brick masonry in the construction, which include:

1. Common Burnt Bricks

Common burnt bricks are divided into clay bricks, shale bricks, gangue bricks and fly ash clay bricks according to the main raw materials.

According to the compressive strength of common burnt bricks, it can be divided into five grades: MU30, MU25, MU20, MU15 and MU10.

According to size deviation, appearance quality, frost and lime burst, common burnt bricks are divided into three grades: high-class, first-class and qualified. High-quality products are suitable for clean water wall, first-class and qualified products can be used for mixed water wall.

The shape of common burnt brick is rectangular hexahedron. Its nominal size is 240mm long, 115mm wide and 53mm high. The specifications of matching bricks are 175 mm x 115 mm x 53 mm.

2. Fly ash Clay Bricks

Fly ash clay bricks are solid bricks made of coal cinder as the main raw material, mixed with appropriate amount of lime and gypsum, which is mixed, pressed or autoclaved.

The shape of fly ash clay bricks are rectangular and its nominal size is 240mm long, 115mm wide and 53mm high.

According to compressive strength and flexural strength, fly ash clay bricks can be divided into four strength grades: MU20, MU15, MU10 and MU7.5.

According to size deviation, appearance quality and strength grade, cinder bricks can be classified as high-class, first-class and qualified products.

3. Porous Bricks

The porous bricks are made from clay, shale and coal gangue by roasting.

The shape of porous bricks are rectangular, and its length, width and height should meet the following requirements:

A.290, 240, 190, 180 mm

B.175, 140, 115, 90mm

According to compressive strength and coefficient of variation, porous brick can be divided into five strength grades: MU30, MU25, MU20, MU15 and MU10.

According to size deviation, appearance quality, strength grade and physical properties of sintered porous brick can be divided into three grades: high-calss, first-class and qualified.

4. Hollow Bricks

The hollow bricks are made of clay, shale and coal gangue by roasting.

The shape of sintered hollow brick is rectangular, and grooves with a depth of more than 1 mm should be set on the interface with mortar.

The length, width and height of hollow bricks shall meet the following requirements:

A. 290, 190, 140, 90 mm

B. 240, 180 (175), 115mm

According to density, hollow brick can be divided into three density levels: 800, 900 and 1100.

Each density level can be divided into three grades, i.e. High-calss, first-class and qualified, according to the number of holes and their rows, size deviation, appearance quality, strength grade and physical properties.

5. Sand-lime Hollow Brick

Sand-lime hollow bricks are made of lime and sand as the main raw materials. The hollow brick with a hole rate less than 15% is made by the preparation and pressing of blanks and autoclaved curing.

According to the compressive strength, the lime-sand hollow brick can be divided into five strength grades: MU25, MU20, MU15, MU10 and MU7.5.

According to strength grade, size allowable deviation and appearance quality, the hollow lime sand can be divided into three grades: first-class product, first-class product and qualified product.

20 Most Important Points in Brick Masonry Construction Supervision

1. The variety and strength of bricks must conform to the design requirements, the specifications are the same,well burnt, with exact shape and size, uniform color and luster.

2. Mortar should meet the design specification. It should have proper consistency and good water retention.

3. When laying bricks, clean up the debris on the beam surface, clean out the loose concrete and copy beam flat.

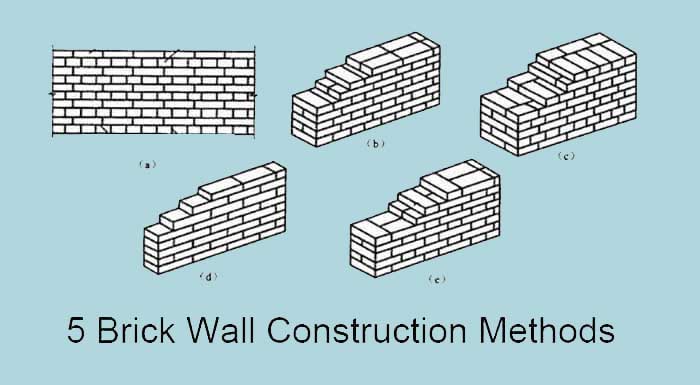

4. When laying bricks, the horizontal line (each brick) should be drawn, and the vertical line should be hung on both sides.

Check the vertical faces of a brick and the inclined surfaces timely.

5. The length of staggered distance is not less than 60MM. The overlapping of staggered joints can ensure that there are no continuous vertical joints in the wall, so as to improve the strength and integrity of the wall.

6. When laying bricks, it should be fully paved with mortar, and the grey joints should be full, straight and with a thickness of 10 mm both horizontally and vertically.

7. Bricks should be staggered from the upper and lower jojnts.

8. Wall surface should be flat and vertical. Flatness and verticality must meet the requirements of specifications.

9. The corner and junction of masonry should be built at the same time.

10. Where corner and T-joint are located, 2Φ6 bent 90° steel must be placed in the horizontal seam. Each side of the steel should be extended into the wall at 1000 MM, with a distance of 500 MM along the wall and 90° hooks at the end.

11. Installation of lightning-proof embedded parts and reserved holes for drainage pipes.

12. No wall should be raised by more than 1.5 m in one day.

13. When plastering or pointing is needed, the face joints should be raised to a depth of 12 to 20 mm.

14. Mortar consistency should observe the requirement.

15. When taking bricks, we should first take the high place and then take the low place, so as to prevent the smashing of people.

16. When chopping bricks, we should hit them inward and pay attention to the impact of broken bricks.

17. Before the typhoon arrives, the built Gables should be temporarily placed between the cross-gables with connecting rods (e.g. trusses) for stable contact. Otherwise, support measures should be taken separately.

18. Tools and materials used for bricklaying should be placed in a safe place.

19. After work, the crushed bricks and mortar on scaffolding and brick walls should be cleaned to prevent falling and injuring people.

20. New construction of brick masonry need to be cured for >2 weeks.

How To Build A Brick Wall | Standards & Quality & Procedure

How To Build A Brick Wall | Standards & Quality & Procedure Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications]

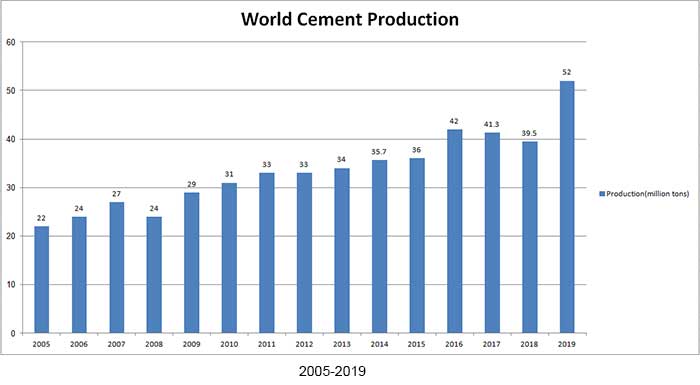

Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications] The Development of Cement History (1756 – 2019)

The Development of Cement History (1756 – 2019) 10+ Rock Types That Can be Used As Building Materials

10+ Rock Types That Can be Used As Building Materials