Bucket Elevator | Structure & Types| How To Choose

Bucket Elevator – How To Work [PDF DOWNLOAD]

What is Bucket Elevator

Bucket elevator is a kind of conveying machine, bucket elevator usually uses a series of buckets which are uniformly fixed to the endless traction chain or belt to continuously lift bulk or broken materials in or near the vertical direction.

Bucket elevator is suitable for lifting convey from low to high, the conveying speed can be adjusted according to the transmission volume, and the lifting height can be selected as needed.

How Does Bucket Elevator Work

The bucket elevator working principle is relatively simple, mainly relying on the bucket hoppers fixed on the chain (belt) to lift the materials flowing evenly into the tail feed port from the tail of the bucket elevator to the head of the bucket elevator uninterruptedly, and then unload the materials from the head outlet to complete the whole lifting process of the materials.

Bucket elevator is suitable for lifting from low to high, the lifting height can reach 40 meters; bucket elevator is generally equipped with casing to prevent dust flying.

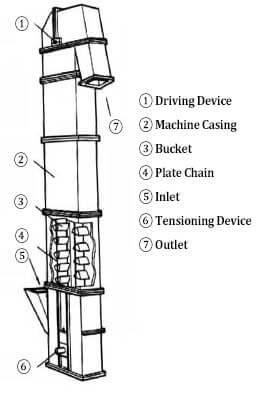

Bucket Elevator Structure

The bucket elevator is mainly composed of traction parts, buckets, driving device, head, barrel, base and so on.

- Traction Parts: there are 2 kinds of traction parts: belt and chain. Belt is generally divided into cotton rubber belt, nylon belt, steel belt. The chain mainly includes HL, forged ring chain, forged square chain as well as plate chain.

- Buckets: carbon steel, stainless steel and polypropylene materials can be selected according to material characteristics.

- Driving Device: the driving device consists of drive drum (or sprocket), motor, reducer, coupling,backstop and driving platform.

- Head: it is composed of head wheel, head shell, discharge port and transmission device. The bucket elevator will install an anti-reverse device on the head wheel shaft toprevent material blockage caused by equipment failure in the process of operation.

- Base: it is composed of machine base shell, bottom wheel, tensioning device, feed hopper and induction devices.

Bucket Elevators Features / Benefits

Bucket elevator is widely used in mining, metallurgy, building materials, coal, hydropower and other industries to vertically lift bulk, granular, powdered materials with a diffuse pressure of less than 250 ℃, such as ore, coal, coke, cement, stone sand etc.

- 1. The bucket elevator adopts flow-in feeding, induced unloading and large-capacity hopper-intensive assembly.

- 2. With a wide range of applications, bucket elevators can be used not only for powdered and small granular materials, but also for materials with large grinding ability.

- 3. There is no need to use bucket to dig materials, extrusion and collision rarely occur between materials, and mechanical wear is reduced, The service life is long.

- 4, Good operation reliability, the advanced design and manufactured method ensure the reliability of the machine, and the fault-free time > 20,000 hours.

- 5. The utility model has the advantages of simple structure, small footprint, reliable work and convenient use and maintenance.

Bucket Elevator Specifications

Get relevant specifications for your business, the recommend bucket elevator specifications a as bellow:

Bucket Elevator Applications

- Glass

- Aggregates

- Minerals

- Cement

- Fertilizers

- Powders

- Suitable for transporting materials below 250 ℃

Bucket Elevator Types

Bucket elevators are mainly used for vertical transportation of powdered, granular and bulk materials, which can be divided into many types. The three common bucket elevators include: Link Chain, Plate Chain and Belt Bucket Elevator:

① Link Chain Bucket Elevator

The bucket elevator with chain structure uses quasi-ring chain as traction component, and the connection between buckets is relatively strong. Suitable for conveying powdered, granular and small bulk materials, such as cement, gravel, sand, chemical fertilizer, etc., the temperature of conveying materials can reach 250 ℃.

② Plate Chain Bucket Elevator

The plate chain bucket elevator has the advantages of light weight, strong structure, fully sealed shell, low chain speed and no material return. It is suitable for lifting large amount of materials, and the temperature of conveying materials can reach 250 ℃.

③ Belt Bucket Elevator

The belt bucket elevator adopts a special design, with tear-proof high-strength steel wire rope core belt, with special belt joint and bucket fixture to make the belt can run reliably for a long time. The temperature of ordinary belt material does not exceed 60 ℃, steel rope belt allows up to 80 ℃, heat-resistant belt allows >120 ℃.

How To Choose A Bucket Elevator

Choosing a right bucket elevator can greatly improve productivity. We recommend to choose bucket elevator from six aspects:

1. Original Information

Before purchasing a bucket elevator, it is necessary to confirm some basic information before selecting the appropriate model:

① Material type, material characteristics, including particle size, loose density, temperature, humidity, viscosity, grindability, etc.

② The actual conveying capacity and the height to be lifted.

2. The Choice of Buckets

The choice of buckets is mainly based on the humidity and viscosity of the material. The shallow bucket is suitable for conveying materials with poor moisture and fluidity, while the deep bucket is suitable for transporting materials with dry and good fluidity.

3. The Choice of Traction Parts

The traction parts of the bucket elevator is an important part to realize the material lifting, which is generally determined according to the elevation of the user and the temperature of the material.

Belt bucket elevator has higher rotational speed and lower cost, but the strength of the belt is low and the lifting height is not large. On the contrary, chain bucket elevator can lift the materials with larger block size and higher temperature.

4. Material loading Mode

The material loading mode of bucket elevator is mainly divided into two types: Cut-Out type and Flow-In type, the choice of both mainly depends on the characteristics and running speed of the materials.

The cut-out type is mainly used for conveying powder, granular and small bulk materials without grinding or semi-grinding, with a high running speed of 0.8-2.0m/s; The flow-in type is used for conveying bulk and grinding materials. The running speed is low and generally does not exceed 1m/s.

5. Material Unloading Mode

The material unloading mode of bucket elevator is divided into centrifugal unloading and gravity unloading, which is selected according to material characteristics, running speed and traction parts types.

Centrifugal unloading is suitable for transporting powdery, granular and small bulk materials with good fluidity, and is mainly used in belt bucket elevator.

Gravity unloading is suitable for transporting bulk and grinding materials, and is suitable for vertical or inclined bucket elevator with continuous arrangement of buckets, the running speed of buckets is about 0.4-0.6m/s.

6. Installation Mode

The installation mode of bucket elevator needs to be based on the on-site conditions of users, and vertical bucket elevators are usually used. The inclined bucket elevator is used only when the vertical bucket elevator can not meet the special requirements, because the supporting device needs to be added when the tilt angle is too large, which makes the structure complicated.

12 Common Bucket Elevator Troubleshooting

12 Common Bucket Elevator Troubleshooting 20 Types of Excavator Buckets and How To Choose A Suitable Bucket

20 Types of Excavator Buckets and How To Choose A Suitable Bucket 8 Tips Help To Choose A Suitable Screw Conveyor

8 Tips Help To Choose A Suitable Screw Conveyor Feeder Machine Types | How To Choose A Feeder Equipment

Feeder Machine Types | How To Choose A Feeder Equipment

Dear Sir / Ma’am,

I hope you will be fine and doing well.

Please quote the best price of below item.

1)BUCKET ELEVATOR PIT LEVEL SWITCH(MEMBRANE LEVEL INDICATOR),

TYPE:MFB-EA,

CHANGE OVER

CONTACT: NO/NC,

CONTACT CAPACITY: 4A/250VAC,

MAKE: MOLLET

QTY: 01

Bucket Elevator 20meter hight

ok sir, we will contact you

Good afternoon,

Please quote price and delivery for Bucket Elevator, Dust Collector and Bin activator as per attached information.

The Bid is due on April 06, 2023, at noon time.

Best Regards,

Rajen Rao

Hello,

We are interested on the Bucket Elevator we need to transport RDF in the Cement Factory.

Material: RDF (Shredded mix Waste)

Size of the RDF: 50mm

Capacity:20-30 cbm/Hour

Bulck density:250-300 kg

Best regards

Adem Viqa