Is Wheel Sand Washer Better Than Spiral Sand Washer ?

Sand washer is an indispensable equipment in sand production process. It can remove dust on the surface of sand and stone and improve the quality of products. Spiral sand washer and wheel sand washer are two common sand washers, but many users consider that spiral sand washer is inferior to wheel sand washer. Now, we introduct the difference of two sand washers as below:

1.Sand Washer Working Principle

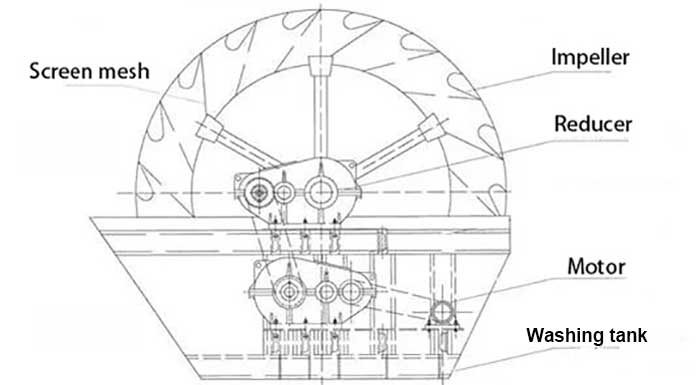

Wheel Sand Washer: When working, the motor drive the impeller runs slowly with the V-belt, gear and reducer. The sand enters the washing launder through the feeding launder, rolls under the impeller and grinds each other to washing out impurities of the gravel. Destroy the water vapor layer of the sand to facilitate dehydration.

Meanwhile, more water is added to wash out foreign bodies that with small impurities and low-weight specific gravity in time, and the overflow liquid discharged from the overflow port to complete the cleaning. The cleaning washed sand will taken away by the impellers.

Spiral Sand Washer: The spiral sand washer should be arranged according to a 15 ° tilt. The bottom of the water tank is surrounded by a three-sided weir plate to form a sedimentation tank. The spiral head is submerged in the sedimentation tank, spiral by a motor through reducer drive continuous rotation, and clean water into the porous plate from the bottom of the tank. The spiral sand washer has three functions: cleaning, dewatering and classifying.

2.Appearance Structure

Wheel sand washer has simple structure, less wearing parts and small footprint. The impeller drive bearing device is isolated from water and water-receiving materials, which basically avoids the damage caused by water, sand and pollutants, and greatly reduces the failure rate.

Spiral sand washer has a relatively long body and a horizontal structure, which is simple and straightforward, but its installation is not as convenient as the wheel type.

3.Sandstone Loss

For wheel-type sand washer, the water consumption during sand washing is less, and the loss of fine sand and stone powder is small. The gradation and fineness modulus of the washed building sand can meet the standard requirements.

4.Cleanliness

Compared with wheel sand washer, sprial sand washer loses more fine sand during cleaning, so it seems that the sand cleaned by spiral sand washer is more clean.

5.Washing Capacity

Spiral sand washer has powerful washing ability, which can wash gravel with serious mud impurities effectively . It is often equipped in large-scale sand production line.

The capacity of wheel washing machine equipment is generally less than 80 tons, so it is suitable for sand production line with small and medium capacity.

6.Sand Washer Price

Wheel sand washer is relatively cheaper, belongs to the economic type of efficient sand washer, and its operation cost is also low.

The price of spiral sand washer is relatively higher, which belongs to the type of high-grade and Large-output sand washer.

7.Single and Double Options

Wheel sand washer can freely choose to increase the number of washing wheels according to the conditions of sand and gravel, so the common equipment is single impeller sand washer, double impeller sand washer, etc. And, fine sand recovery units can also be installed on the side of the washing wheel, butt installation is very convenient.

If the clay content of sand and gravel is high or the output is to be increased, the spiral sand washer can also increase the length of the auger shaft or use double helix side by side, so it can also be divided into single screw sand washer and double screw sand washer.

Wheel sand washer is relatively cheaper in price, and its processing capacity is not as good as spiral sand washer, but it can meet the requirements of most sand washing production lines. Therefore, wheel sand washer is more widely used in actual production.

However, when choosing sand washer, users should consider the composition of sand and gravel, expected production capacity, factory site conditions and other factors, choose the most suitable machines for their requirements.

Spiral Washers VS Spiral Classifiers

Spiral Washers VS Spiral Classifiers Types of Sand Washer

Types of Sand Washer Sand Washer Machine In Malaysia

Sand Washer Machine In Malaysia 11 Common Faults of Sand Washer and Solutions

11 Common Faults of Sand Washer and Solutions