How To Select Sand Making Machine?

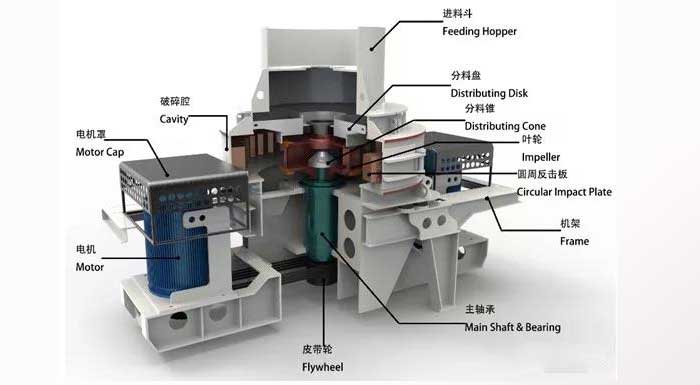

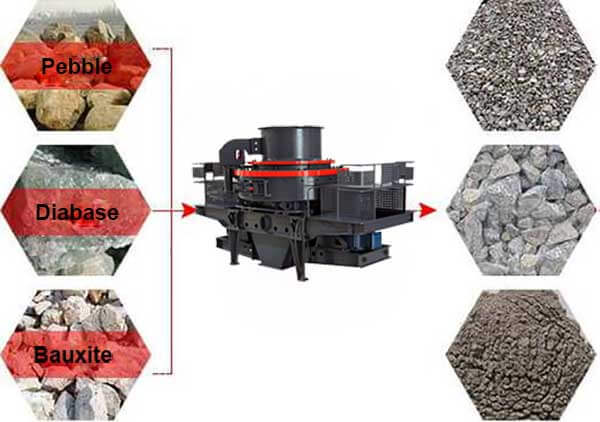

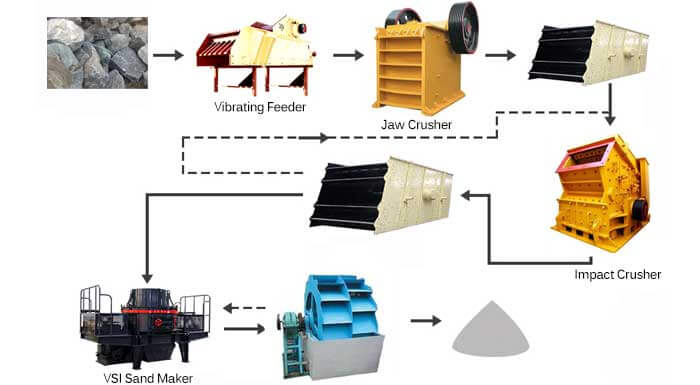

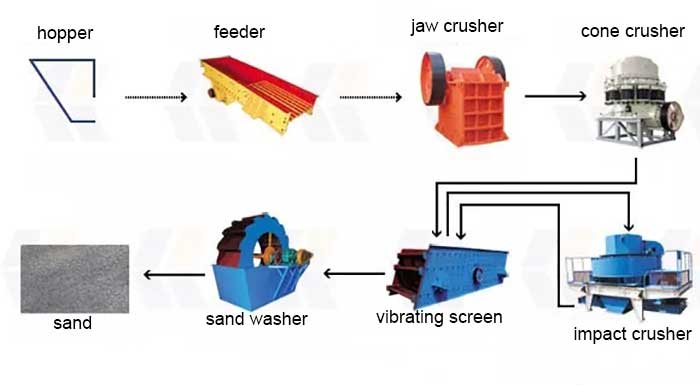

Sand making machine, also known as vertical shaft impact crusher (VSI), is mainly used to make sand. VSI crusher is a kind of high-energy and low-consumption impact crusher with international advanced level. VSI crusher is the most effective, practical and reliable crushing machine.

Sand making machine is the core equipment in a sand and aggregate making production line, and the sand making machine is related to the finished machine made sand quality, so many factors should be considered when choosing a sand making machine.

The Factors that Affect Sand Making Machine

How To Select Sand Making Machine [PDF DOWNLOAD]

1. Feed Particle Size

In the design of artificial sand making system, the particle size of feed materials should be considered first. Generally, if raw materials < 25 mm and grading better, the sand making system will work efficiency and achieve large sand production.

2. Material Moisture Content

The moisture content of raw materials will also affect the sand making efficiency. When the moisture content exceeds 2%, the separation efficiency of the screen will be reduced. Therefore, for the dry process production technology, we must consider the rainproof.

3. Environmental Protection of Equipment

Sand making machine must conform to the concept of green environmental protection and be able to strictly control noise and dust pollution.

4. Quality of Equipment Materials

If the quality of equipment purchased is poor, frequent breakdowns may occur in use, thus delaying the construction time and affecting the production schedule.

5. Word-of-Mouth Credibility

Manufacturers with good reputation will guarantee the quality of equipment and produce more professionally. Through on-the-spot visits, visits to determine whether the sand machine is good or not.

6. After-Sales Service

After sales service is the guarantee for smooth production in the future. The formal manufacturers must have a professional after-sale engineer team.

The selection of sand making machines is the key link in the design of sand making system, which directly affects the quality and cost of sand and aggregates production.

When selecting equipments, the properties of source rocks, gradation and quality requirements of finished sand and aggregates products and technical performance of main equipments should be fully studied. It should be technologically advanced, economically rational and ensure the reliability of the system.

VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications A 800 TPH Sand Making Plant Details

A 800 TPH Sand Making Plant Details Wet Sand Making VS Dry Sand Making

Wet Sand Making VS Dry Sand Making 3 Million Granite Sand Making Production Line

3 Million Granite Sand Making Production Line

Requerimos para un nuevo montaje de arena silice separar los metales pesados y clasificar en todas las granulometrías hasta la malla 400.

Composición del material

80% arena gruesa

20% piedra máximo 3″ pulgadas.

Un saludo

My company need of one powder making unit.

Grinding material Marbal

Size from mine 15″

Wanted 225 mesh thickness

Capacity 150-200 t/day (8-10 hours working)

Full all in all plant.

💞💞💞💞💞💞💕

Aggregate two project

Two 200 TPH tyre mounted plant for crushing in one of stone from river and in other from blasting.

In feed in River Gravel 600 mm n

in Blast stone 750 mm

in end need sand -3.75mm,

Aggregate – 10 mm, 18 mm, 25 mm

and some time – 32 mm, 45 mm also

———-

For our other site, now needs of a Sand VSI, those can produce <2 mm, dust

free for 100-125 MT/hr capacity.

Your hydraulic JAW which type? "V"

Chamber and Body?

💞💕💞💕💞💞💕💞💕

Sand making only?

With dust removal?

125 t/hr. Capacity in both

A. <4.75 mm 100%

B. <2.00 mm 100℅

Full line prize with machine detail and lay out

<0.075 mm too remove

💙💙💙💙💙💙💙💙

My,

er.nagpal@yahoo.com

gravitaglobal@gmail.com

Skype er.nagpal@yahoo.com