Hot Types of Road Rollers | How To Buy A Road Roller

A road roller is an engineering machinery equipment used for road construction and maintenance, mainly used for compacting soil and road surface, leveling road surface, compacting roadbed and foundation layer, compacting paving materials, and repairing road surface defects. There are various types of road rollers that can be selected according to different work requirements and working conditions.

1. Light Wheel Roller

The light wheel roller is mainly used for compacting asphalt pavement and concrete surfaces. Its working principle is to use heavy-duty smooth steel wheels to roll on the ground and use the pressure generated by its own weight to compact the road surface.

Light wheeled rollers usually adopt a simple structural design, which makes them highly reliable and has a relatively low failure rate during use. The advantage of a light wheel roller is its uniform compaction effect, but its effectiveness is limited when dealing with loose soil. Mainly used for foundation compaction and road compaction of gravel, crushed stone, asphalt concrete, sand and gravel mixture, low viscosity soil, lime, coal slag, etc.

2. Load Roller

Load roller is a type of roller specifically designed for heavy-duty earthworks and foundation engineering. It is usually equipped with multiple heavy-duty tires, which can generate a larger contact area and more effectively compact the soil.

Load rollers are particularly suitable for compacting soft soil or loose materials, and are particularly common in the construction of large foundations, embankments, and fill projects. In addition, it can also be used to compact different types of pavement materials, such as asphalt, cement, sand and gravel.

Although the load roller performs well in compacting soft soil and loose materials, its compaction depth is relatively limited. For projects that require deep compaction, other types of rollers or auxiliary equipment may need to be used.

3. Vibratory Roller

The vibratory roller uses the principle of vibration for compaction and is usually equipped with a pair of adjustable vibration wheels that can generate strong vibration force, enhancing the compaction effect of the soil.

The vibratory roller can compact materials that are difficult to compact with static action rollers, such as large particle backfill stones, and can also compact dry and hard cement concrete. When compacting the asphalt concrete surface layer, due to the vibration effect, the asphalt material of the surface layer can fully penetrate and soften with other aggregates, resulting in good wear resistance and low repair rate of the road surface.

Vibration rollers are suitable for various soil types, especially performing well in handling loose materials such as clay, sand, and gravel.

4. Multi Wheel Roller

A multi wheel roller is a type of roller composed of multiple wheels, usually equipped with two or more sets of tires, which can form a larger compacted area on the road surface. Multi wheel rollers utilize the weight and vibration energy of the machine itself to compact loose particles, soil, and other materials on the road, achieving good compaction results. This compaction method helps to reinforce the road structure, improve the bearing capacity and durability of the road.

Multi wheel rollers are suitable for various road compaction work, including new road construction and maintenance and repair of existing roads, and can achieve compaction in a relatively short period of time. Whether it is compacting soil, gravel, asphalt concrete and other materials, multi wheel rollers can perform excellently.

5. Self Propelled Roller

Self propelled roller is a type of modern roller equipped with a power system that can walk on its own. This type of roller is not only convenient for operators to control, but also can be flexibly moved on different construction sites.

Self propelled road rollers are generally equipped with advanced automatic control systems, which can adjust pressure and vibration frequency according to work needs, have high work efficiency, and can quickly compact the road surface, shortening the construction period.

How To Buy A Roller

- Construction and Use: Understanding the construction environment and specific use of rollers is particularly important. Different types of rollers are suitable for different soil types and construction conditions. Before purchasing, the project requirements should be clearly defined.

- Specifications and Performance: The specifications and performance of a roller directly affect its working efficiency and compaction effect. When selecting, attention should be paid to parameters such as the working weight, drum width, and vibration frequency of the roller.

- Brand and After-Sales Service: Well known brands usually have better technical support and after-sales service systems, which can provide timely repair and maintenance when equipment problems occur. At the same time, it is also necessary to understand the warranty policy of the equipment and the supply of spare parts.

- Budget and Cost: Developing a reasonable budget and conducting cost-benefit analysis are also important steps when selecting a roller. It is necessary to comprehensively consider factors such as the purchase cost, maintenance cost, and service life of the equipment to ensure the selection of a roller with higher cost-effectiveness within the budget.

What Is Asphalt Concrete | Types & How Is It Made

What Is Asphalt Concrete | Types & How Is It Made Hot Types of Asphalt Pavement | [8 Types & Features]

Hot Types of Asphalt Pavement | [8 Types & Features] Types of Sand Washer

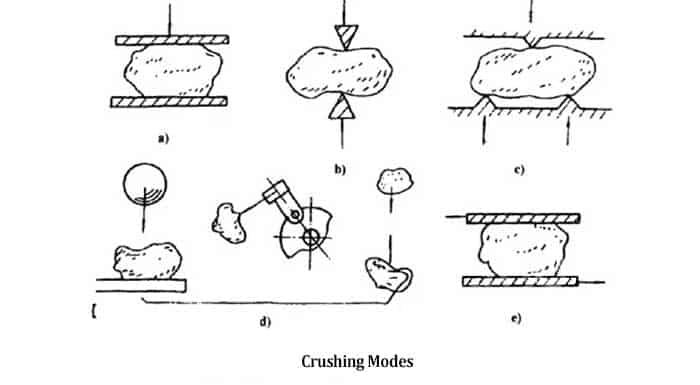

Types of Sand Washer Different Crushing Types Among 7 Crushers

Different Crushing Types Among 7 Crushers