Cement Rotary Kiln | Structure & Working Principle | Types | Features

What Is Cement Rotary Kiln

Cement rotary kiln, also known as cement kiln, is a device mainly used for heating and treating loose or slurry materials. Cement rotary kiln is the core equipment in cement production, playing a decisive role in the quality of cement. A good cement kiln has high output, stable operation, good product quality, and strong market competitiveness.

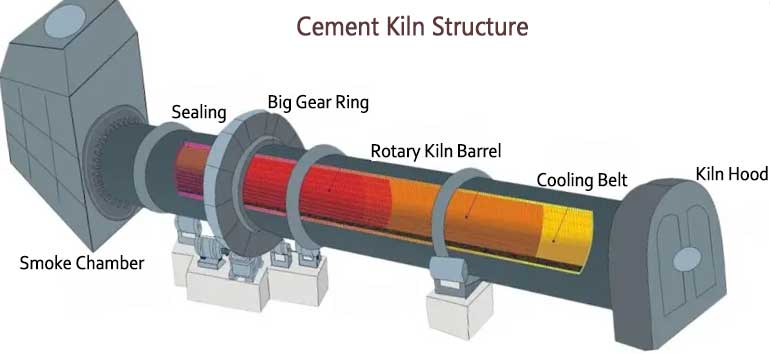

Cement Kiln Structure & Working Principle

The cement rotary kiln is a cylindrical object with a certain slope, with a slope of 3-3.5%. It is mainly composed of burner, kiln head cover, cylinder, wheel, support device, large gear ring, transmission device, smoke chamber, feeding chamber, etc. The entire kiln body is supported by a supporting wheel device, and there is a blocking wheel device that controls the up and down movement of the kiln body. The transmission system is also equipped with auxiliary transmission devices. Efficient sealing devices are used at the kiln head and tail.

Working Principle:

- Feeding: Raw materials (cement clinker, fuel, and auxiliary materials) enter the rotary kiln from the feeding port, forming a material layer.

- Rotary Motion: The rotary kiln begins to rotate, and the material gradually slides down and moves forward under the action of gravity and centrifugal force.

- Drying, Preheating, Calcination, and Cooling: Fuel is sprayed from the kiln head and burned inside the kiln, emitting heat to heat the raw materials. The material undergoes processes such as drying, preheating, calcination, and cooling in the kiln, ultimately generating clinker. The exhaust gas formed during the heating process is treated by bag filters or cyclone dust collectors set at the kiln head and tail.

- Discharge: The cooled clinker is discharged from the discharge port of the rotary kiln and sent to the clinker silo for storage.

During the operation of cement kilns, equipment such as preheaters, coolers, and dust collectors are required to cooperate with their work. A preheater is used to preheat and partially decompose materials, allowing for better utilization of heat. The cooler is used to quickly cool down high-temperature materials. Dust collectors are used to treat the dust and smoke generated during the material calcination process. Promote effective emission reduction of exhaust gas and rational utilization of resources.

Cement Kiln Types and Parameters

Cement Rotary Kiln Features

As a key equipment in cement production, cement rotary kiln has its unique advantages and disadvantages.

Advantages:

- H-Efficient: The design of the cement rotary kiln allows the raw materials to be uniformly affected by high-temperature heat energy, allowing some difficult to melt substances to fully react. The material temperature inside the cement rotary kiln ranges from 1450 ℃ to 1550 ℃, while the gas temperature can reach as high as 1700 ℃ to 1800 ℃. The complete decomposition of toxic and harmful components in waste.

- Large Capacity: The cement rotary kiln can process a large amount of raw materials at once, meeting the requirements of large-scale production.

- High Quality: High temperature sintering technology can fully react and melt raw materials, forming high-quality cement clinker. The total residence time of materials from the kiln tail to the kiln head is about 35 minutes, and the residence time of gases above 950 ℃ is more than 8 seconds; A residence time above 1300 ℃ for more than 3 seconds is more conducive to the combustion and decomposition of waste.

- No Waste Residue: In cement production, only raw materials and the clinker that produced through calcination process, without the slag produced by general incinerators.

- Multifunctionality: Cement rotary kilns can also be used in the production of refractory materials, mineral processing, chemistry, and other fields.

- Intelligent Control: Modern cement rotary kilns are equipped with intelligent control systems, which can accurately control the temperature inside the kiln, ensure product quality, and automatically send out alarm signals in case of abnormal situations to avoid accidents.

- Sturdy Structure: The cement rotary kiln has the characteristics of being sturdy, durable, with few vulnerable parts, and high operating rate.

Disadvantages:

- Difficulty In Maintenance: Cement rotary kilns operate for long periods of time in high temperature, high humidity, and high dust environments, with a relatively short service life that requires frequent maintenance and replacement.

- Environmental Pollution: During the cement production process, a large amount of harmful gases and solid waste are emitted, causing certain pollution to the environment.

- High Energy Consumption: Cement rotary kilns have high energy consumption and need to improve energy utilization efficiency.

- Circle Formation: Rotary kiln circle formation increases the resistance of gas and material movement, reduces product quality, and even requires kiln shutdown for cleaning.

Screw Conveyor Features | Working Principle and Types

Screw Conveyor Features | Working Principle and Types Spiral Chute | Working Principle | Features | Specification

Spiral Chute | Working Principle | Features | Specification How To Classify Cement ?

How To Classify Cement ? Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features